Proper wheel bearing maintenance is crucial for vehicle safety, performance, and longevity. As we look ahead to 2024, advances in automotive technology place new demands on these vital components. This comprehensive guide covers everything mechanics and drivers need to know about caring for wheel bearings in the coming year.

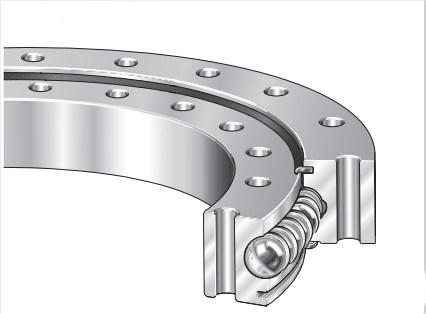

Understanding Wheel Bearings Wheel bearings allow the wheel hub to rotate smoothly with minimal friction around the axle or spindle. These steel ball or tapered roller bearings are packed with grease and sealed inside a metal casing mounted on each wheel. Over time, the bearings can wear due to heat, water/dirt contamination, and high mileage.

Signs of Worn Wheel Bearings Catching wheel bearing issues early is key to avoiding potential catastrophic failure.

Warning signs include:

- Growling, grinding, or rumbling noises from the wheel area

- Abnormal wheel vibration or wobble, especially at higher speeds

- Uneven tire wear due to poor wheel tracking

- Loose or excessive play in the wheel when rocked

Wheel Bearing Inspection & Service Many automakers recommend inspecting wheel bearings annually after 25,000-30,000 miles.

The mechanic will:

- Lift the vehicle and rock the wheel to check for play

- Spin the wheel to listen/feel for roughness

- Examine the bearing grease condition and replenish if needed

Replacement is necessary for any bearings showing signs of wear, damage, roughness, or excessive play beyond specifications.

Wheel Bearing Replacement Tips for 2024 As vehicles become more technologically advanced, proper wheel bearing service grows increasingly important:

- Always use quality replacement bearings meeting OEM specs from trusted suppliers

- Follow the manufacturer’s detailed replacement procedure

- Use the correct specialized tools for bearing removal, installation, and repacking

- Pack new bearings with the specified high-temp grease

- Adjust bearing preload precisely per instructions

For 2024 models with electronic parking brakes, wheel speed sensors, stability control, and self-driving features – incorrect wheel bearing installation can negatively impact these systems.

Wheel Bearing Maintenance Best Practices To maximize wheel bearing longevity:

- Maintain proper air pressure in tires

- Rotate tires regularly and balance after replacement

- Avoid pothole impacts, curb strikes, and extreme driving conditions

- Have worn suspension components replaced promptly

- Use a high-quality grease meeting specifications for regreasing

By adhering to this ultimate wheel bearing maintenance guide for 2024, you can minimize noise, vibration, and premature bearing wear – promoting safer driving, optimal fuel economy, and extended vehicle life.

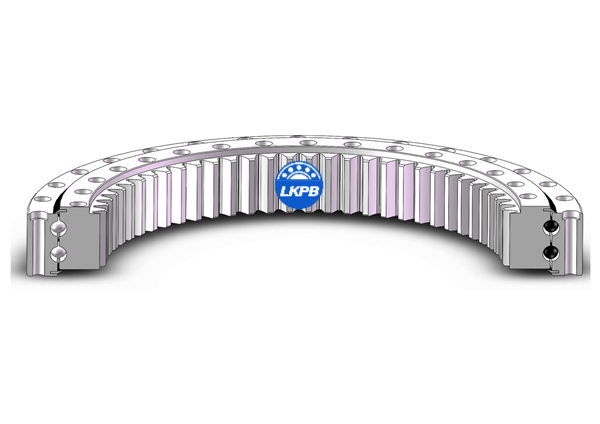

About LKPB Bearing Company

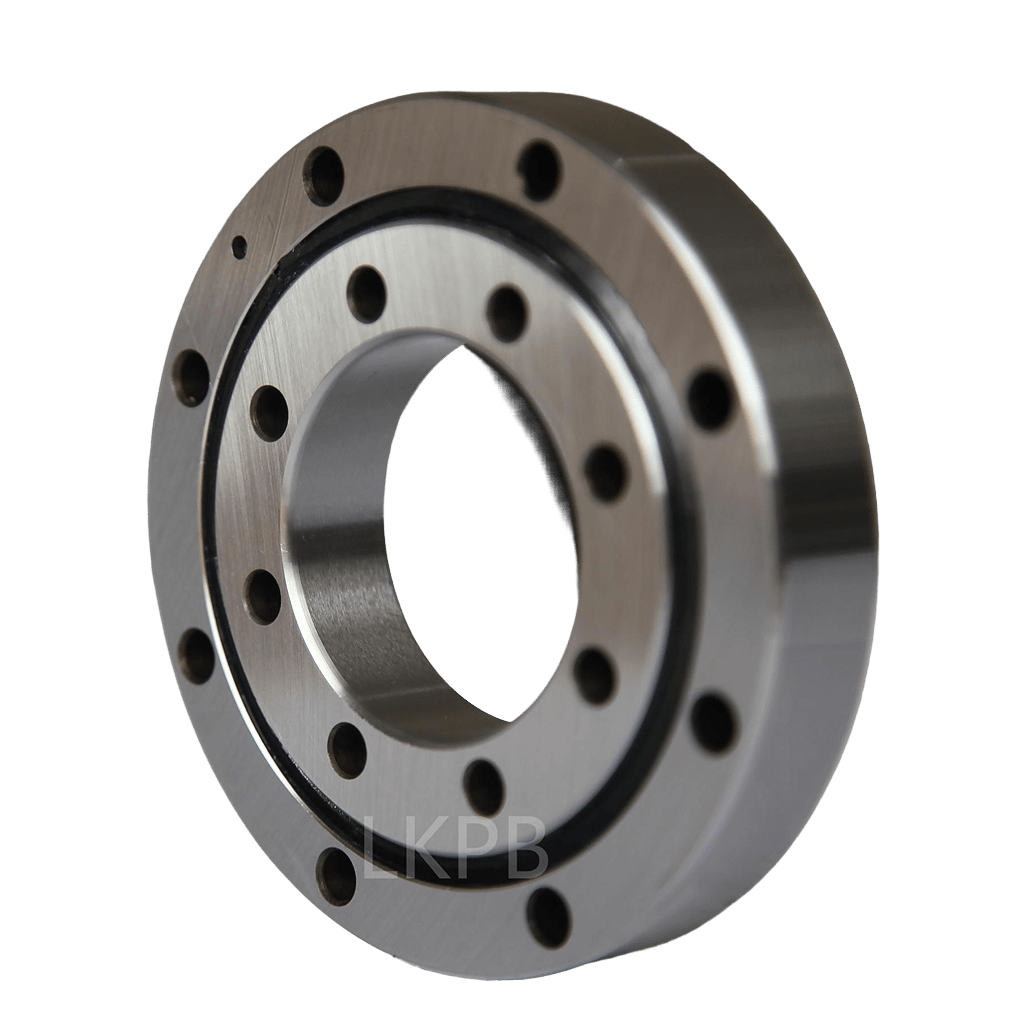

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional bearing manufacturer.

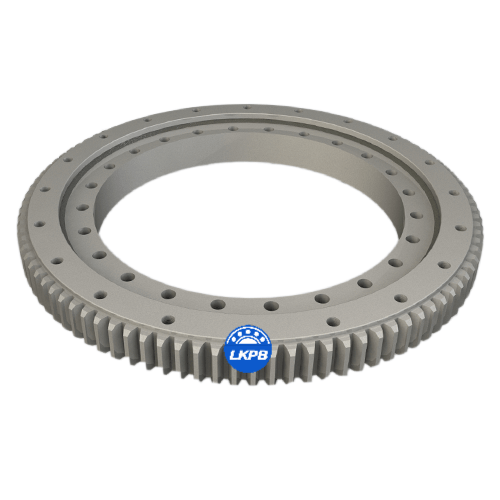

LKPB strictly follows the ISO9001 quality system requirements for product quality control, we have a strong technical team to accept processing of non-standard precision bearings of P5, P4, P2 and VSP level of accuracy. The products inner diameter size range is φ20mm-φ2000mm.

We have established long term co-operation with a number of the world’s leading machine tool and robotics companies, the products can completely replace of INA/IKO/THK/FAG/SKF/KAYDON and other brands. We believe that cooperating with us will exceed your expectations.

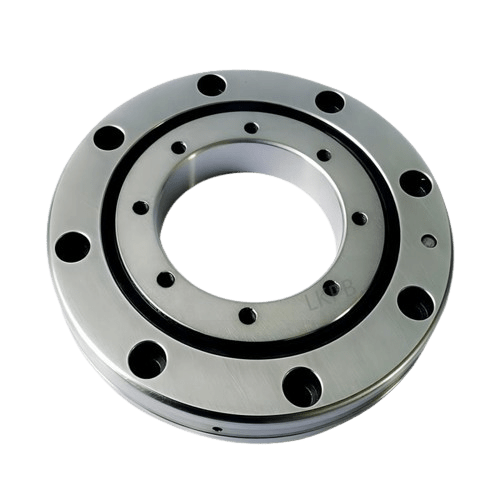

- Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

- Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

- Thin Section Ball Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

- Robot Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

- Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

- Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF/ZARN Series);

- Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

- Hollow Rotary Platform Bearings ( ZK Series).

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty