In the ever-evolving world of industrial machinery and equipment, bearings play a pivotal role in ensuring smooth and efficient operations. These critical components are responsible for reducing friction, minimizing wear and tear, and facilitating seamless rotational movements. As such, choosing the right bearing manufacturer is a decision that can significantly impact the performance, reliability, and longevity of your machinery. In this comprehensive guide, we’ll explore the essential factors to consider when selecting a bearing manufacturer, helping you make an informed choice that aligns with your unique requirements and business objectives.

Understanding the Importance of High-Quality Bearings

Bearings are the unsung heroes that keep industrial machinery running smoothly, enabling precise movements and supporting heavy loads. From automotive applications to wind turbines, bearings are foundational components that contribute to the overall efficiency and reliability of equipment.

The Impact of Inferior Bearings on Operational Costs: Compromising on bearing quality can have severe consequences, leading to increased downtime, frequent maintenance requirements, and even catastrophic equipment failures. These setbacks can result in substantial financial losses, missed production targets, and damage to your company’s reputation. By investing in high-quality bearings from reputable manufacturers, you can mitigate these risks and ensure long-term operational efficiency and cost-effectiveness.

Evaluating Potential Bearing Manufacturers: A Comprehensive Checklist

Expertise and Industry Experience: When evaluating potential bearing manufacturers, their expertise and industry experience should be at the forefront of your assessment. Look for companies with a proven track record and a deep understanding of bearing applications, materials, and manufacturing processes. Manufacturers with extensive industry knowledge can provide valuable insights and recommendations tailored to your specific requirements.

Manufacturing Capabilities and Quality Control: High-quality bearings are the result of stringent manufacturing processes and rigorous quality control measures. Investigate the manufacturer’s production facilities, technologies, and quality assurance protocols to ensure they adhere to industry standards and best practices. Reputable manufacturers prioritize quality at every stage, from raw material sourcing to final product inspection.

Customizable Solutions and OEM Services: In today’s rapidly evolving industrial landscape, flexibility and adaptability are key. Look for bearing manufacturers that offer customizable solutions and OEM (Original Equipment Manufacturer) services. Companies like LKPB excel in accommodating non-standard bearing requirements, allowing you to optimize your machinery and equipment for specific applications or unique design constraints.

Global Sourcing and Supply Chain Efficiency: While China is a major hub for bearing production, consider manufacturers with a global presence and sourcing capabilities. Manufacturers with an international footprint can offer a wider range of options, access to diverse manufacturing facilities, and the ability to serve customers worldwide effectively. Additionally, evaluate their supply chain efficiency, including inventory management, shipping methods, and responsiveness to urgent orders.

Competitive Pricing and Value-Added Services: While cost should not be the sole deciding factor, finding a balance between quality and affordability is essential. Research and compare bearing prices from various manufacturers to ensure you’re getting a fair deal without compromising on product quality or performance. Furthermore, look for manufacturers that offer value-added services such as technical support, product training, and maintenance advice, which can help you maximize the lifespan and performance of their bearings.

The LKPB Advantage: A Trusted Partner for Superior Bearing Solutions

LKPB: A Leading Bearing Manufacturer with a Commitment to Excellence: LKPB has established itself as a premier bearing manufacturer, renowned for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art manufacturing facilities and a team of experienced engineers, LKPB offers a comprehensive range of bearings tailored to meet the demands of diverse industries.

Embracing Customization and OEM Services: Understanding the unique challenges faced by its customers, LKPB excels in providing customizable bearing solutions and OEM services. Whether you require bearings for specialized machinery, extreme operating conditions, or unique design constraints, LKPB’s expertise in custom bearing design ensures that you obtain products that meet your exact specifications, reducing the need for costly modifications or compromises.

Quality Assurance and Rigorous Testing: At LKPB, quality is ingrained in every aspect of their operations. From stringent raw material inspections to comprehensive product testing, LKPB adheres to the highest industry standards and quality control measures. This unwavering commitment to quality ensures that every bearing leaving their facilities meets or exceeds performance expectations, providing you with peace of mind and reliable operation.

Competitive Pricing and Value-Added Support: LKPB understands the importance of balancing quality with affordability. By leveraging their global sourcing capabilities and streamlined supply chain, they offer competitive pricing without sacrificing quality. Additionally, LKPB provides value-added services such as technical support, product training, and maintenance advice, ensuring that you can maximize the lifespan and performance of their bearings.

By choosing LKPB as your trusted bearing manufacturer, you gain access to a partner that prioritizes quality, innovation, and customer satisfaction. With their expertise in customization, commitment to rigorous testing, and value-added support, LKPB positions itself as a reliable choice for businesses seeking exceptional bearing solutions.

Embark on a Journey Towards Operational Excellence

In the dynamic world of industrial operations, choosing the right bearing manufacturer is a critical step towards achieving operational excellence. By considering the essential factors outlined in this guide, you can navigate the complexities of bearing procurement with confidence, identifying manufacturers that align with your unique requirements and propel your business towards long-term success.

Remember, investing in high-quality bearings is an investment in the longevity and efficiency of your machinery, ultimately impacting your bottom line and competitive edge. Embrace the pursuit of quality, seek out manufacturers that offer customizable solutions and value-added services, and prioritize partnerships that foster innovation and continuous improvement.

With a strategic approach and the right bearing manufacturer by your side, you can unlock a world of operational excellence, where seamless machinery performance, reduced downtime, and optimized productivity become the norm. Embark on this journey today and experience the transformative power of superior bearing solutions from industry-leading manufacturers like LKPB.

About LKPB Bearing Company

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional bearing manufacturer.

LKPB strictly follows the ISO9001 quality system requirements for product quality control, we have a strong technical team to accept processing of non-standard precision bearings of P5, P4, P2 and VSP level of accuracy. The products inner diameter size range is φ20mm-φ2000mm.

We have established long term co-operation with a number of the world’s leading machine tool and robotics companies, the products can completely replace of INA/IKO/THK/FAG/SKF/KAYDON and other brands. We believe that cooperating with us will exceed your expectations.

- Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

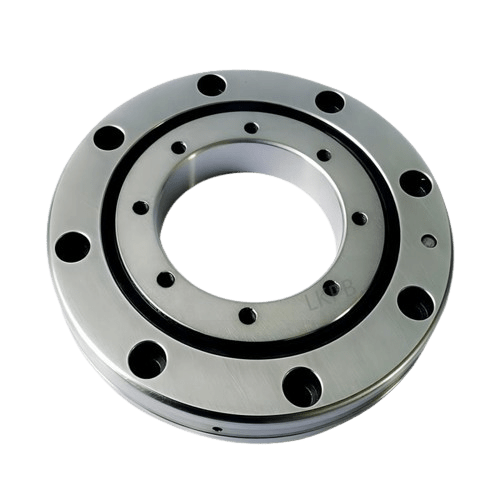

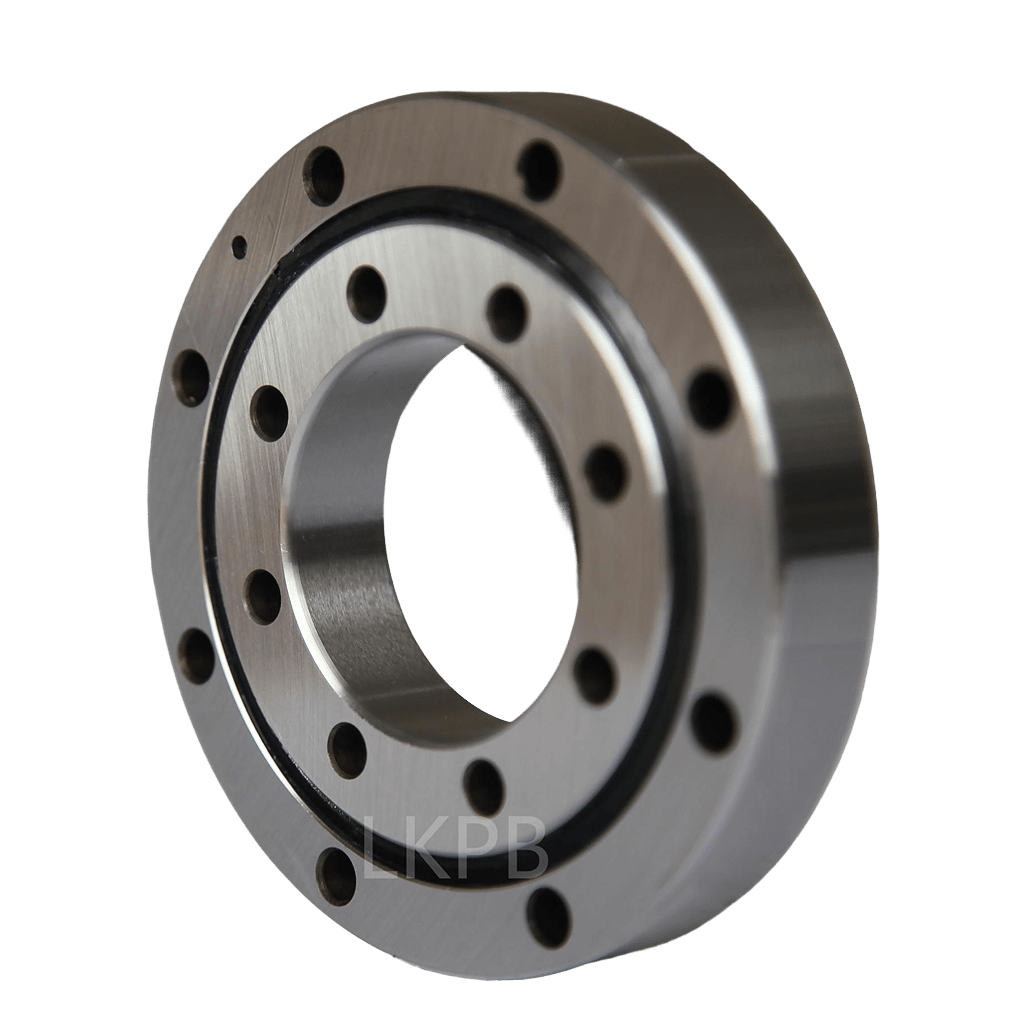

- Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

- Thin Section Ball Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

- Robot Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

- Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

- Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF/ZARN Series);

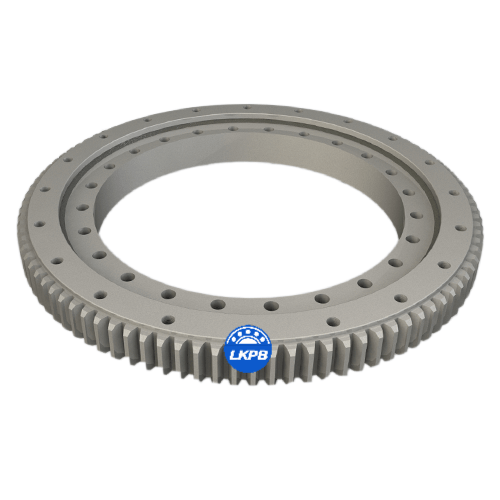

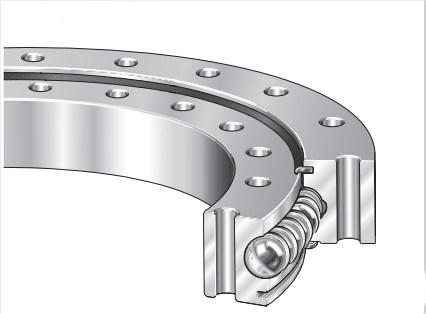

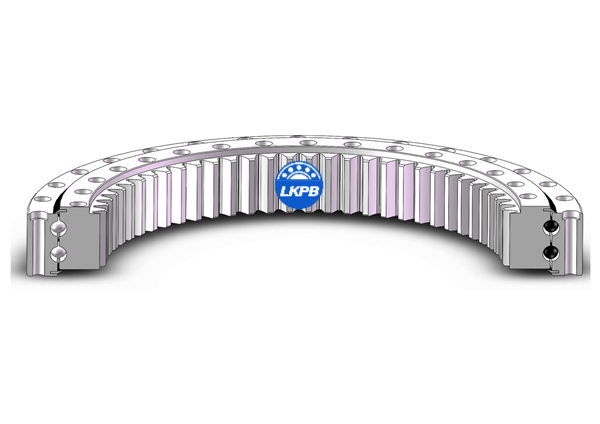

- Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

- Hollow Rotary Platform Bearings ( ZK Series).

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty