About Bearings

Bearings are mechanical components that support rotating shafts or axles and enable smooth rotational motion between two parts. They are used in a wide range of applications, including motors, wheels, gears, and various kinds of machinery. Bearings serve several important functions:

1. Reducing friction: Bearings minimize the friction between the rotating shaft and the stationary housing, allowing for smoother rotation and reduced energy loss.

2. Supporting loads: Bearings are designed to support radial loads (perpendicular to the shaft) and, in some cases, thrust loads (parallel to the shaft).

3. Positioning: Bearings help maintain the proper positioning and alignment of the rotating components.

4. Distributing loads: Bearings distribute the load evenly across their rolling elements (e.g., balls, rollers), preventing localized stress and wear.

There are several types of bearings, including:

1. Ball bearings: These use small spherical balls as the rolling elements and are suitable for high-speed applications.

2. Roller bearings: These use cylindrical rollers as the rolling elements and can handle heavier radial loads.

3. Thrust bearings: These bearings are designed to support thrust loads parallel to the shaft.

4. Sleeve bearings: These are simple bushings or plain bearings that rely on a lubricating film between the shaft and the bearing surface.

Bearings can be made from various materials, such as steel, ceramic, or plastic, depending on the application’s requirements for load capacity, durability, and operating conditions (e.g., temperature, lubrication).

Proper selection, installation, and maintenance of bearings are crucial for ensuring efficient and reliable operation of rotating machinery.

China has made significant strides in developing its precision bearing industry in recent years. Here are some key insights:

- Increased focus on R&D: Chinese bearing manufacturers have been investing heavily in research and development to improve the quality, precision, and performance of their bearings. This has allowed them to catch up with international standards and compete more effectively in the global market.

- Adoption of advanced manufacturing technologies: Chinese companies have been adopting advanced manufacturing technologies, such as computer numerical control (CNC) machining, precision grinding, and surface treatment processes, to enhance the accuracy and reliability of their precision bearings.

- Expansion of product range: While China initially focused on producing standard bearings, many Chinese companies have expanded their product range to include high-precision bearings for various applications, including aerospace, automotive, and industrial machinery.

- Emphasis on quality control: To meet the stringent requirements of precision bearings, Chinese manufacturers have implemented robust quality control measures, such as clean-room environments, stringent inspection processes, and adherence to international quality standards like ISO 9001.

- Domestic market growth and international expansion: The growing demand for precision bearings in China’s domestic market, driven by industries like automotive, wind energy, and high-speed rail, has fueled the growth of the precision bearing industry. Additionally, Chinese bearing manufacturers have been actively pursuing international markets, leveraging their competitive pricing and improving quality.

- Collaboration and acquisitions: Some Chinese bearing companies have formed strategic partnerships or acquired foreign companies to gain access to advanced technologies, expertise, and established distribution networks.

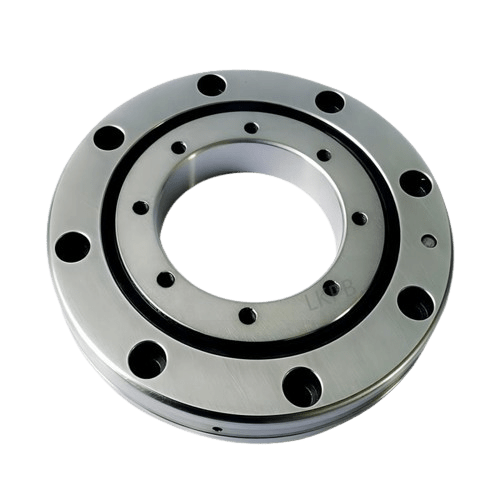

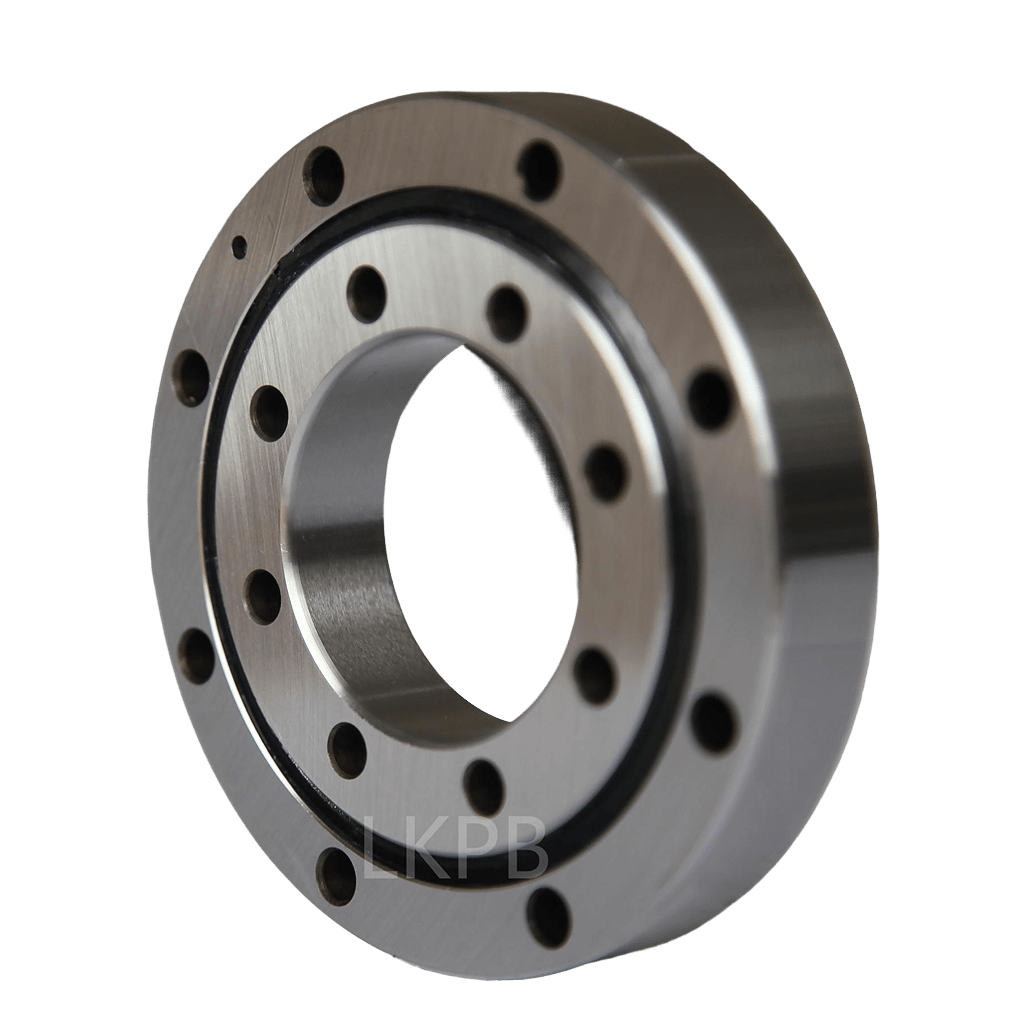

Our precision bearing products

Our bearing applications

About LKPB Bearing Company

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional bearing manufacturer.

LKPB strictly follows the ISO9001 quality system requirements for product quality control, we have a strong technical team to accept processing of non-standard precision bearings of P5, P4, P2 and VSP level of accuracy. The products inner diameter size range is φ20mm-φ2000mm.

We have established long term co-operation with a number of the world’s leading machine tool and robotics companies, the products can completely replace of INA/IKO/THK/FAG/SKF/KAYDON and other brands. We believe that cooperating with us will exceed your expectations.

- Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

- Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

- Thin Section Ball Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

- Robot Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

- Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

- Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF/ZARN Series);

- Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

- Hollow Rotary Platform Bearings ( ZK Series).

Latest articles on bearings

The Top Flange Bearing Trends to Watch in 2024

Flange bearings are essential components in a wide range of industrial applications, providing reliable support and smooth rotational motion for

Innovative Types of Roller Bearings for Industrial Applications in 2024

As we approach 2024, the industrial sector is witnessing a surge in demand for innovative and high-performance roller bearings. These

Small Roller Bearings: A Comprehensive Buyer’s Guide for 2024

In the ever-evolving world of precision engineering, small roller bearings play a crucial role in enabling smooth and efficient motion

The Ultimate Guide to Choosing Tapered Roller Bearings

Understanding Tapered Roller Bearings Tapered roller bearings are a specific type of rolling element bearing designed to accommodate combined radial

Exploring the Advantages and Disadvantages of Different Bearing Types

Introduction Bearings are essential components in countless mechanical systems, enabling smooth and efficient rotational or linear motion between parts. With

THK/IKO/HIWIN Bearing Number Meaning

Introduction to Bearing Numbering Systems In the world of bearings, each manufacturer has its own unique numbering system to identify

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty