In the ever-evolving landscape of precision manufacturing, CNC (Computer Numerical Control) machine tools have become indispensable workhorses, enabling high-speed, accurate, and consistent production across various industries. At the heart of these sophisticated machines lies a critical component – the rotary table bearing – which plays a pivotal role in ensuring smooth and precise rotational movements, essential for achieving exceptional machining accuracy and efficiency.

Understanding CNC Machine Tools

CNC machine tools are automated manufacturing systems that utilize computer-controlled cutting tools to shape, drill, or mill a wide range of materials, including metals, plastics, and composites. These versatile machines are extensively used in industries such as aerospace, automotive, medical, and consumer product manufacturing, where precision and repeatability are paramount.

CNC machine tools are designed to operate with high levels of accuracy, speed, and consistency, enabling complex shapes and intricate details to be machined with exceptional precision. These machines are equipped with advanced control systems, robust structures, and specialized components to meet the demanding requirements of modern manufacturing processes.

The Importance of Rotary Table Bearings in CNC Machine Tools

Rotary table bearings are essential components in CNC machine tool design, enabling the precise and controlled rotational movements required for accurate machining operations. These specialized bearings are engineered to withstand the extreme conditions and heavy loads encountered in high-speed machining environments, while providing superior precision and rigidity.

The selection of the appropriate rotary table bearing is crucial for the efficient and accurate operation of CNC machine tools. Key factors to consider include:

- Load Capacity: Rotary table bearings must be capable of supporting the combined radial and axial loads imposed by the workpiece, cutting forces, and operational forces encountered during machining operations.

- Precision and Rigidity: High levels of precision and rigidity are essential for rotary table bearings to ensure accurate positioning and minimal deflection during machining processes, contributing to the overall dimensional accuracy of the finished parts.

- High-Speed Capability: Many CNC machine tool applications involve high-speed machining operations, requiring rotary table bearings that can withstand high rotational speeds while maintaining smooth and consistent performance.

- Durability and Wear Resistance: The harsh operating conditions in CNC machining environments, such as exposure to coolants, chips, and abrasive particles, necessitate the use of durable and wear-resistant rotary table bearings to extend service life and minimize downtime.

- Customization and Design Flexibility: The diverse range of CNC machine tool applications often requires customized rotary table bearing solutions tailored to specific design constraints and performance criteria.

In August 2020, LKPB successfully partnered with a UK** company on a CNC Machine Tools project.

Before the customer used INA rotary table bearings, bearing price is high, long delivery time, after the introduction and comparison of my company’s technical staff, LKPB bearings in all aspects are very advantageous, but the customer is worried about the quality of our bearings and INA bearings have a gap, hesitate to make a decision, after three months of uninterrupted sample testing, the customer has a better understanding of the company’s products, the results of the test are no problem, and the INA bearings performance parameters are consistent, LKPB bearings good quality and low price won the customer’s recognition, the subsequent establishment of a long-term relationship with the customer. The performance parameters of LKPB bearings are the same, LKPB bearings have been recognized by customers for their good quality and low price, and we have established a long-term cooperative relationship with them.

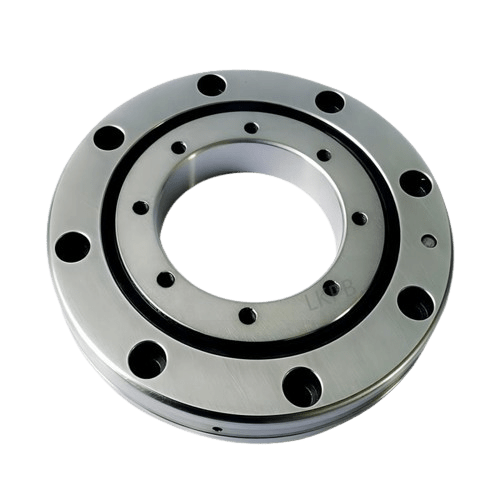

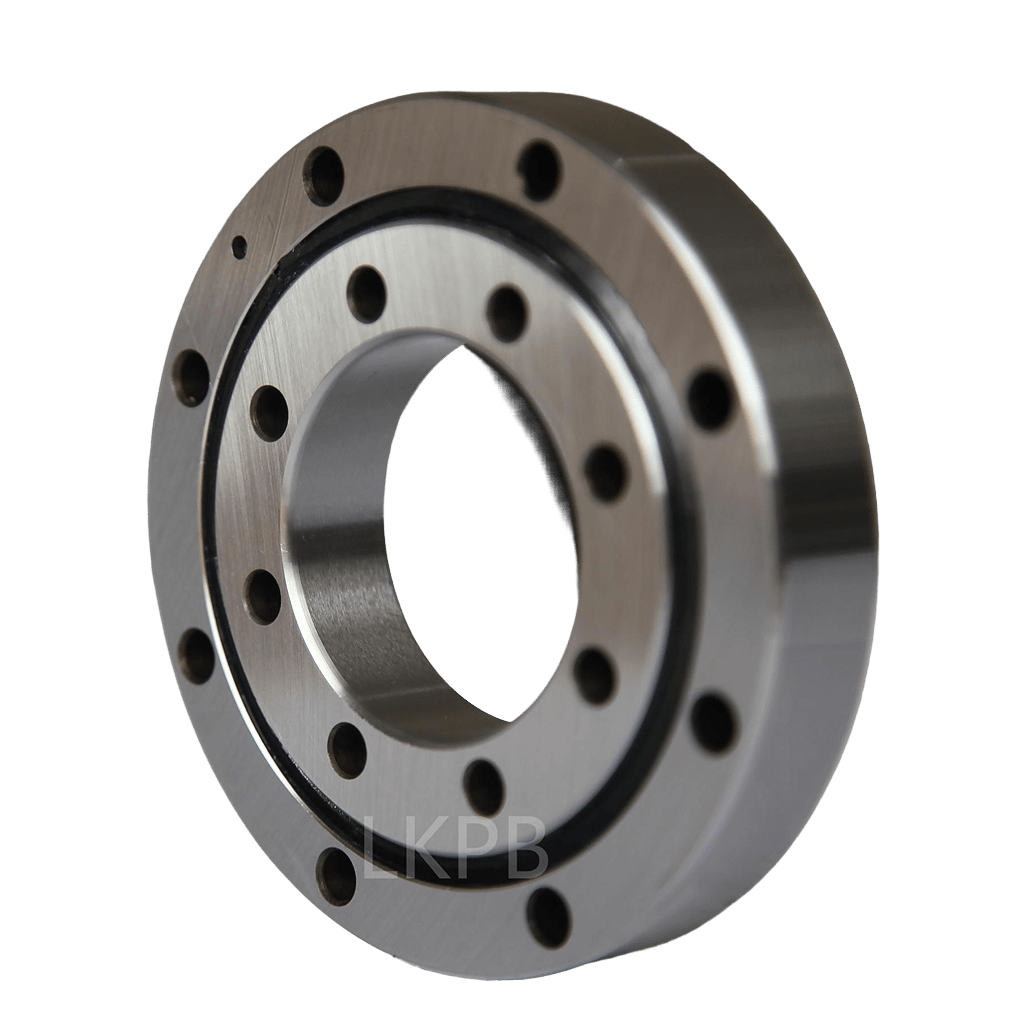

Our products are mainly used in the customer’s horizontal machining center machine tool rotary table, the use of the bearing type YRT260, YRT325, YRT395 and YRT580, the accuracy of P2 grade.

LKPB rotary table bearings

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Product precision can be P5, P4, P2 and VSP, Inside diameter size range φ20mm – φ2000mm. Maximum product quality warranty of 24 months, OEM acceptable.

LKPB With more than 10 years of production experience, The most professional suppliers of precision bearings in China.

Are your products reliable?

LKPB® strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective,

LKPB®, turning the world, carrying unlimited! We have served thousands of customers all over the world during the ten years of our establishment.

Our future goal is to become the most professional manufacturer of rotary table bearings and crossed roller bearings in China, and make LKPB® a world-class bearing brand.

This is our vision and direction!

Do you have export experience?

LKPB® has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

1. Precision Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series)

2. Precision Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

3. Precision Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

4. Robot Harmonic Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

5. Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

6. Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF, ZARN Series);

7. Precise Slewing Bearring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

8. Hollow Rotary Platform Bearings ( ZK Series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time