In the rapidly evolving world of industrial automation, robotics has emerged as a game-changing technology, transforming manufacturing processes and revolutionizing productivity across various sectors. At the heart of these sophisticated robotic systems lies a critical component – the cross roller bearing – which plays a pivotal role in enabling precise, smooth, and reliable movements essential for industrial robotics applications.

Understanding Industrial Robotics

Industrial robots are programmable, multi-functional machines designed to perform a wide range of tasks with exceptional precision, speed, and consistency. These robots are extensively used in various industries, including automotive, electronics, aerospace, and healthcare, to streamline manufacturing processes, enhance quality control, and improve overall efficiency.

Industrial robots are typically composed of several articulated joints and linkages, allowing for complex movements and intricate positioning. These joints require specialized bearings capable of handling combined radial, axial, and moment loads while ensuring smooth rotation and precise positioning.

The Advantages of Cross Roller Bearings in Industrial Robotics

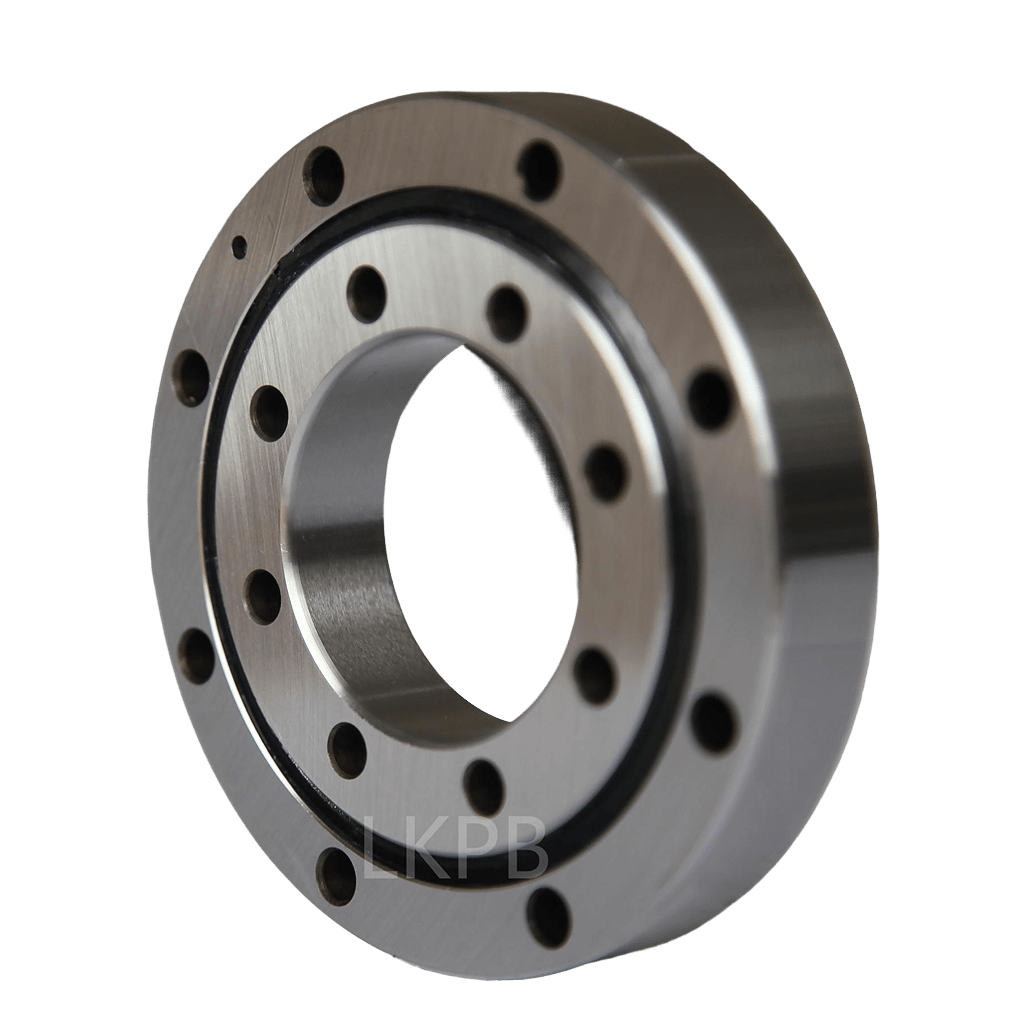

Cross roller bearings are uniquely suited for industrial robotics applications due to their exceptional load-carrying capacity, compact design, and ability to accommodate both radial and axial loads simultaneously. These bearings offer several advantages that make them an ideal choice for robotic systems:

- High Load Capacity: Cross roller bearings are designed to withstand substantial radial and axial loads, making them well-suited for supporting the weight and dynamic forces of robotic arms and joints.

- Compact and Space-Saving Design: With their unique cross roller arrangement, these bearings have a compact and space-saving design, allowing for more efficient integration into robotic systems with limited space constraints.

- Precise and Smooth Movements: The cross roller configuration enables precise and smooth rotational movements, ensuring accurate positioning and reducing vibrations, which is critical for robotic applications requiring high levels of precision.

- Increased Rigidity: Cross roller bearings offer superior rigidity compared to other bearing types, making them ideal for applications involving high moment loads, such as those encountered in robotic welding or material handling operations.

- Versatility and Customization: Cross roller bearings can be customized to meet specific application requirements, including specialized materials, coatings, and sealing options, providing manufacturers with the flexibility to tailor solutions for their unique robotic systems.

Applications of Cross Roller Bearings in Industrial Robotics

Cross roller bearings find widespread applications in various industrial robotics systems, including:

- Articulated Robotic Arms: Cross roller bearings are commonly used in the joints and linkages of articulated robotic arms, facilitating smooth and precise movements essential for tasks such as welding, painting, assembly, and material handling.

- Robotic Gantry Systems: These bearings are employed in robotic gantry systems, enabling precise linear and rotational movements for pick-and-place operations, palletizing, and other material handling tasks.

- Robotic Welding and Cutting Systems: The high load capacity and rigidity of cross roller bearings make them suitable for robotic welding and cutting applications, where precise positioning and smooth movements are crucial for achieving high-quality welds and cuts.

- Collaborative Robots (Cobots): In the emerging field of collaborative robotics, cross roller bearings play a vital role in ensuring safe and precise interactions between humans and robotic systems, enabling seamless cooperation in various manufacturing and assembly processes.

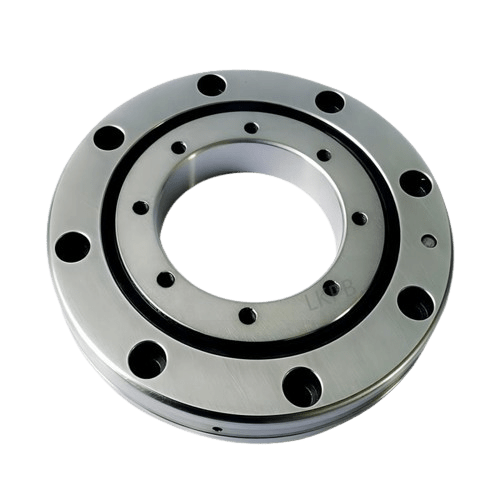

In August 2018, we established a partnership with a Korean **company** that has been using LKPB’s RA Series Cross Roller Bearings.

The customer had been purchasing THK bearings before, but because of the high price, long lead time and the inability to provide customized, LKPB provided customized RA Cross Roller Bearings for the customer because of the special requirements on friction torque, oil filling quantity and rotational speed of the bearings.

LKPB's Cross Roller Bearings

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Product precision can be P5, P4, P2 and VSP, Inside diameter size range φ20mm – φ2000mm. Maximum product quality warranty of 24 months, OEM acceptable.

LKPB With more than 10 years of production experience, The most professional suppliers of precision bearings in China.

Are your products reliable?

LKPB® strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective,

LKPB®, turning the world, carrying unlimited! We have served thousands of customers all over the world during the ten years of our establishment.

Our future goal is to become the most professional manufacturer of rotary table bearings and crossed roller bearings in China, and make LKPB® a world-class bearing brand.

This is our vision and direction!

Do you have export experience?

LKPB® has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

1. Precision Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series)

2. Precision Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

3. Precision Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

4. Robot Harmonic Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

5. Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

6. Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF, ZARN Series);

7. Precise Slewing Bearring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

8. Hollow Rotary Platform Bearings ( ZK Series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time