Introduction:

In the dynamic landscape of industrial machinery and automation, the RW Double-Row Angular Contact Roller Ring emerges as a pinnacle of engineering innovation. This article explores the key features, advantages, and applications of the RW Double-Row Angular Contact Roller Ring, shedding light on how this component contributes to the enhancement of precision and efficiency in various industrial settings.

Innovative Angular Contact Design:

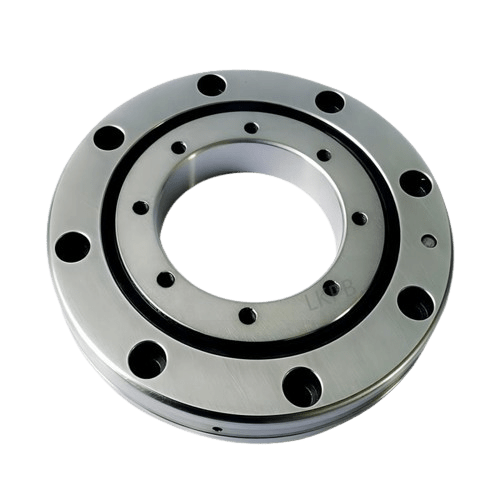

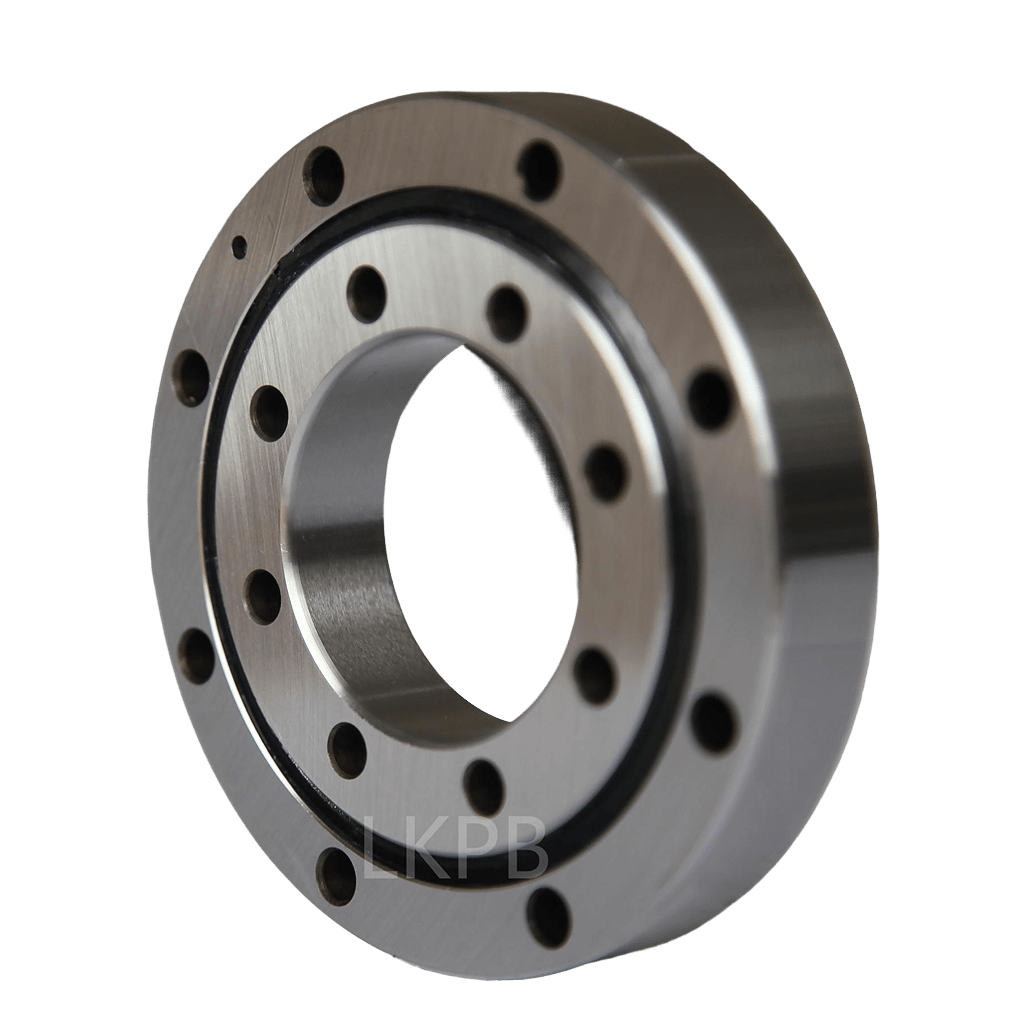

RW Double Row Crossed Roller Bearings (Integral Inner and Outer Rings with Mounting Holes)

The inner and outer rings of RW double row crossed roller bearings have an integrated structure, which realizes high rigidity of the parts. The inner and outer rings are provided with mounting holes, and the size and number of holes are optimized to reduce deformation of the rolling surface caused by mounting, resulting in stable rotational performance. In addition, by improving the machining accuracy, the rotational accuracy can be improved.

The RW Double-Row Angular Contact Roller Ring distinguishes itself through its innovative angular contact design. The double-row configuration allows for enhanced axial and radial load-carrying capabilities, making it an ideal solution for applications where both types of loads are present. This design also facilitates high rigidity, ensuring stability and precision in rotational motion.

Versatility Across Industries:

One of the noteworthy aspects of the RW Double-Row Angular Contact Roller Ring is its versatility. This component finds applications across a spectrum of industries, including machine tools, robotics, construction equipment, and more. The ability to accommodate complex loads while maintaining high precision makes it a reliable choice for engineers and designers facing diverse challenges in rotational motion control.

Enhanced Load-Carrying Capacity:

The double-row design of the RW Angular Contact Roller Ring significantly enhances its load-carrying capacity. This is particularly advantageous in applications where heavy loads and dynamic forces are prevalent. The bearing’s ability to distribute loads effectively ensures longevity and reliability, even in demanding industrial environments. Engineers can rely on this component to deliver consistent performance under varying operational conditions.

Precise Angular Contact for Motion Control:

Precision is a cornerstone of the RW Double-Row Angular Contact Roller Ring’s design. The angular contact arrangement minimizes friction and allows for precise control of rotational movements. This characteristic is invaluable in applications that require accurate positioning, such as CNC machines, where even slight deviations can impact the quality of the end product. The precision of the angular contact design contributes to improved overall system performance.

Sealed and Lubricated for Reliability:

Recognizing the importance of reliability and longevity, the RW Double-Row Angular Contact Roller Ring is equipped with effective sealing mechanisms to protect against contaminants and ensure optimal lubrication. This feature minimizes the risk of premature wear and extends the bearing’s service life, reducing maintenance requirements and downtime.

Customization Options for Varied Requirements:

Engineers and designers benefit from the customization options available with the RW Double-Row Angular Contact Roller Ring. Whether it’s size variations, specific load requirements, or environmental considerations, the component can be tailored to meet the unique specifications of different applications. This flexibility underscores RW’s commitment to providing solutions that align seamlessly with the diverse needs of industries.

Conclusion:

The RW Double-Row Angular Contact Roller Ring stands as a testament to precision engineering, versatility, and reliability in the realm of rotational motion control. With its innovative angular contact design, enhanced load-carrying capacity, and customization options, this component addresses the evolving demands of modern industries. As engineers seek to optimize the performance of machinery and automation systems, the RW Double-Row Angular Contact Roller Ring remains a go-to solution for achieving the precision and efficiency required in today’s dynamic industrial landscape.

RW Double-Row Angular Contact Roller Ring introduction

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Product precision can be P5, P4, P2 and VSP, Inside diameter size range φ20mm – φ2000mm. Maximum product quality warranty of 24 months, OEM acceptable.

LKPB With more than 10 years of production experience, The most professional suppliers of precision bearings in China.

Are your products reliable?

LKPB® strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective,

LKPB®, turning the world, carrying unlimited! We have served thousands of customers all over the world during the ten years of our establishment.

Our future goal is to become the most professional manufacturer of rotary table bearings and crossed roller bearings in China, and make LKPB® a world-class bearing brand.

This is our vision and direction!

Do you have export experience?

LKPB® has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

1. Precision Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

2. Precision Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

3. Precision Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

4. Robot Harmonic Reducer Bearings (CSF/CSG, SHF/SHG, Z Series and Flexible Bearings F, 3E Series);

5. Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

6. Ball Screw Support Bearings (ZKLF(N), ZARF, ZARN Series);

7. Hollow Rotary Platform Bearings ( ZK Series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time