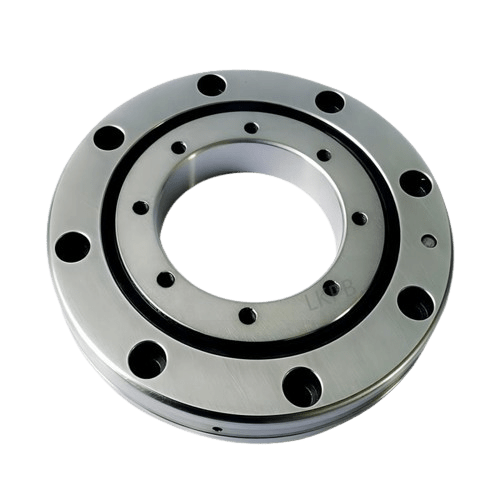

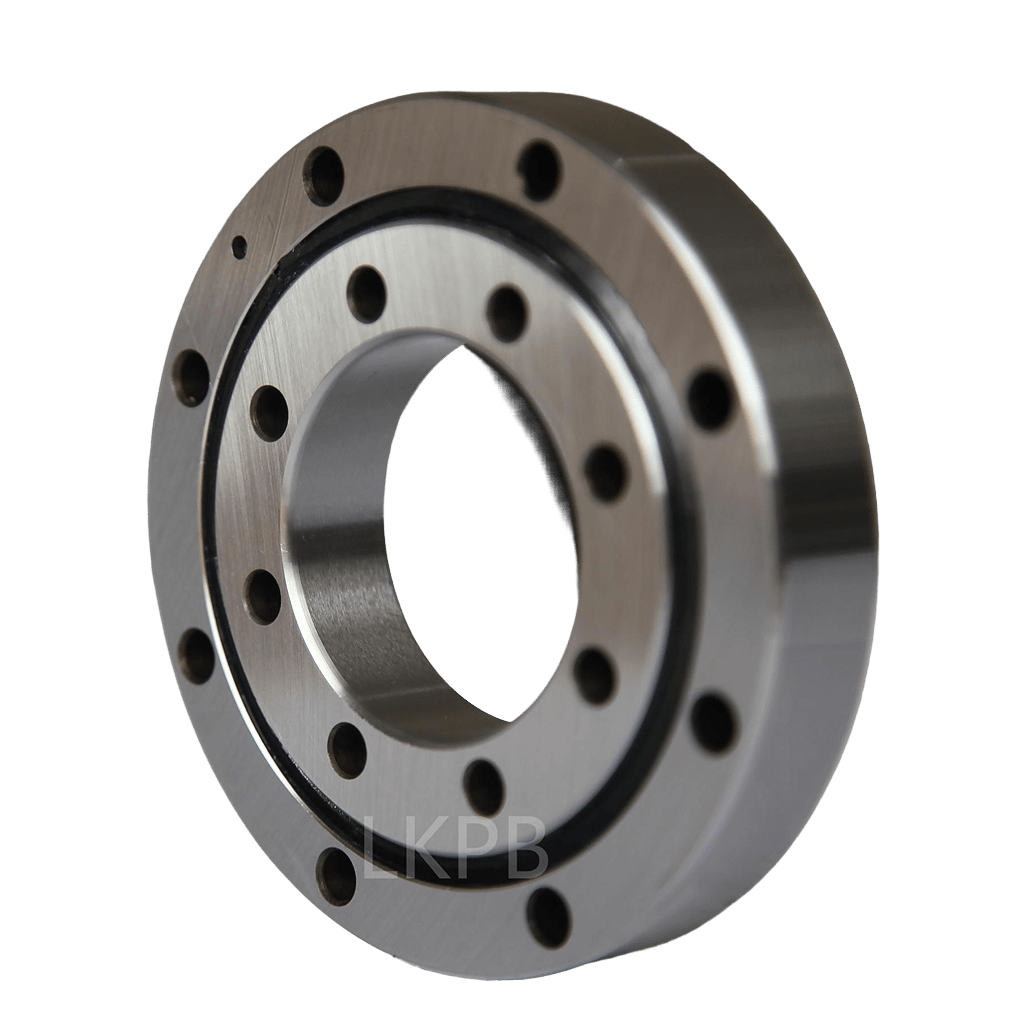

Three-Row Roller Slewing Ring Bearings, also called three-row cylindrical roller combination slewing ring bearings, is a kind of bearing with high load carrying capacity, which is mainly used in occasions with large loads. This slewing bearing has three seating rings, the upper, lower and radial raceways are separated, so that each row of rollers can bear axial and radial loads respectively, and it is one of the four products with higher load carrying capacity. In this kind of turntable bearing, the axial force and tilting torque are borne by the upper and lower rows of horizontal rollers; the radial force is borne by the third row of rollers arranged vertically. It is widely used in medium and large cranes and excavators and other construction machinery, construction machinery, metallurgy, port lifting equipment, ship cranes and other equipment with large loads are also widely used three rows of cylindrical roller combination slewing ring bearings.

Three rows of cylindrical roller combination slewing ring bearings simultaneously bear axial load, tilting moment and radial load. Compared with crossed cylindrical roller slewing disc bearings, the load per roller is reduced, and compared with double-row radial ball slewing disc bearings, the contact stresses are reduced by moving from point contact to line contact. As a result, the load carrying capacity is greater, under the same shape and size conditions. The axial and radial loads of this structure are carried by different rollers, where the axial load and tilting moment are carried by two sets of rollers placed horizontally by the shaft, and the radial load is carried by one set of rollers placed vertically by the shaft.

External Tooth Type Three-Row Roller Slewing Ring Bearings Product Parameters

| LKPB Model | Overall dimensions | Mounting Dimensions | Tooth parameter | Payloads | Weights | ||||||||||||||

| De | de | di | Di | He | Hi | Ht | Fe | Ne | V | Fi | Ni | V | m | z | Dp | x·m | |||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [-] | [mm] | [-] | [mm] | [-] | [mm] | [mm] | [kN] | [kg] | |||

| E-0500 | 665 | 526 | 537 | 366 | 116 | 138 | 148 | 598 | 24 | 18 | 402 | 24 | 18 | 5 | 130 | 650 | 5 | 2750 | 224 |

| E-0560 | 725 | 586 | 597 | 426 | 116 | 138 | 148 | 658 | 24 | 18 | 462 | 24 | 18 | 5 | 142 | 710 | 5 | 3080 | 240 |

| E-0630 | 808 | 593 | 604 | 496 | 116 | 138 | 148 | 728 | 28 | 18 | 532 | 28 | 18 | 8 | 98 | 784 | 8 | 3450 | 270 |

| E-0710 | 888 | 673 | 684 | 576 | 116 | 138 | 148 | 808 | 28 | 18 | 612 | 28 | 18 | 8 | 108 | 864 | 8 | 3880 | 300 |

| E-0800 | 1008 | 830 | 841 | 636 | 142 | 172 | 182 | 920 | 36 | 22 | 680 | 36 | 22 | 8 | 123 | 984 | 8 | 5490 | 500 |

| E-0900 | 1104 | 930 | 941 | 736 | 142 | 172 | 182 | 1020 | 36 | 22 | 780 | 36 | 22 | 8 | 135 | 1080 | 8 | 6190 | 600 |

| E-1000 | 1220 | 1030 | 1041 | 836 | 142 | 172 | 182 | 1120 | 40 | 22 | 880 | 40 | 22 | 10 | 119 | 1190 | 10 | 6890 | 680 |

| E-1120 | 1340 | 1150 | 1161 | 956 | 142 | 172 | 182 | 1240 | 40 | 22 | 1000 | 40 | 22 | 10 | 131 | 1310 | 10 | 7680 | 820 |

| E-1250 | 1512 | 1200 | 1210 | 1055 | 170 | 210 | 220 | 1393 | 45 | 26 | 1107 | 45 | 26 | 14 | 105 | 1470 | 14 | 11100 | 1200 |

| E-1400 | 1666 | 1350 | 1360 | 1205 | 170 | 210 | 220 | 1543 | 45 | 26 | 1257 | 45 | 26 | 14 | 116 | 1624 | 14 | 12400 | 1300 |

| E-1600 | 1872 | 1550 | 1560 | 1405 | 170 | 210 | 220 | 1743 | 48 | 26 | 1457 | 48 | 26 | 16 | 114 | 1824 | 16 | 14200 | 1520 |

| E-1800 | 2072 | 1840 | 1850 | 1605 | 170 | 210 | 220 | 1943 | 48 | 26 | 1657 | 48 | 26 | 14 | 145 | 2030 | 14 | 15900 | 1750 |

| E-2000 | 2304 | 1945 | 1967 | 1779 | 177 | 219 | 231 | 2155 | 60 | 33 | 1845 | 60 | 33 | 18 | 125 | 2250 | 18 | 20500 | 2400 |

| E-2240 | 2556 | 2185 | 2207 | 2019 | 177 | 219 | 231 | 2395 | 60 | 33 | 2085 | 60 | 33 | 18 | 139 | 2502 | 18 | 23100 | 2700 |

| E-2500 | 2820 | 2445 | 2467 | 2279 | 177 | 219 | 231 | 2655 | 72 | 33 | 2345 | 72 | 33 | 20 | 138 | 2760 | 20 | 25800 | 3000 |

Internal Tooth Type Three-Row Roller Slewing Ring Bearings Product Parameters

| LKPB Model | Overall dimensions | Mounting Dimensions | Payloads | Weights | |||||||||||

| De | de | di | Di | He | Hi | Ht | Fe | Ne | V | Fi | Ni | V | |||

| [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [-] | [mm] | [-] | [kN] | [kg] | |||

| U-0500 | 634 | 526 | 537 | 366 | 138 | 116 | 148 | 598 | 24 | 18 | 402 | 24 | 18 | 2750 | 224 |

| U-0560 | 694 | 586 | 597 | 426 | 138 | 116 | 148 | 658 | 24 | 18 | 462 | 24 | 18 | 3080 | 240 |

| U-0630 | 764 | 656 | 667 | 496 | 138 | 116 | 148 | 728 | 28 | 18 | 532 | 28 | 18 | 3450 | 270 |

| U-0710 | 844 | 736 | 747 | 576 | 138 | 116 | 148 | 808 | 28 | 18 | 612 | 28 | 18 | 3880 | 300 |

| U-0800 | 964 | 830 | 841 | 636 | 172 | 142 | 182 | 920 | 36 | 22 | 680 | 36 | 22 | 5490 | 500 |

| U-0900 | 1064 | 930 | 941 | 736 | 172 | 142 | 182 | 1020 | 36 | 22 | 780 | 36 | 22 | 6190 | 600 |

| U-1000 | 1164 | 1030 | 1041 | 836 | 172 | 142 | 182 | 1120 | 40 | 22 | 880 | 40 | 22 | 6890 | 680 |

| U-1120 | 1284 | 1150 | 1161 | 956 | 172 | 142 | 182 | 1240 | 40 | 22 | 1000 | 40 | 22 | 7680 | 820 |

| U-1250 | 1445 | 1290 | 1300 | 1055 | 210 | 170 | 220 | 1393 | 45 | 26 | 1107 | 45 | 26 | 11100 | 1200 |

| U-1400 | 1595 | 1440 | 1450 | 1205 | 210 | 170 | 220 | 1543 | 45 | 26 | 1257 | 45 | 26 | 12400 | 1300 |

| U-1600 | 1795 | 1640 | 1650 | 1405 | 210 | 170 | 220 | 1743 | 48 | 26 | 1457 | 48 | 26 | 14200 | 1520 |

| U-1800 | 1995 | 1840 | 1850 | 1605 | 210 | 170 | 220 | 1943 | 48 | 26 | 1657 | 48 | 26 | 15900 | 1750 |

| U-2000 | 2195 | 2041 | 2055 | 1816 | 137 | 117 | 150 | 2127 | 60 | 33 | 1885 | 60 | 33 | 16900 | 1120 |

| U-2240 | 2461 | 2273 | 2295 | 2019 | 219 | 177 | 231 | 2395 | 60 | 33 | 2085 | 60 | 33 | 23100 | 2700 |

| U-2500 | 2721 | 2533 | 2555 | 2279 | 219 | 177 | 231 | 2655 | 72 | 33 | 2345 | 72 | 33 | 25800 | 3000 |

LKPB Three-Row Roller Slewing Ring Bearings Product Features

- Material: 42CrMo, 50Mn

- Seal type: Nitrile rubber

- Characteristics: four-point

- contact inner teeth / outer teeth / no teeth

- Inner diameter size: 100-8000mm

- Outside diameter: 200-10000mm

- Warranty: 12 months

- Rolling body: steel ball

- Normalized hardness: 187HB-241HB

- Tempering hardness: 229HB-269HB

- Raceway quenching hardness: HRC 55-62

- Non-standard models can be designed and manufactured according to customer requirements.

- Optimization of the sealing structure or redesign of the internal retainer according to customer requirements.

- Packing: metal stand or export standard non-fumigation wooden case.

About LKPB Bearing Company

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional bearing manufacturer.

LKPB strictly follows the ISO9001 quality system requirements for product quality control, we have a strong technical team to accept processing of non-standard precision bearings of P5, P4, P2 and VSP level of accuracy. The products inner diameter size range is φ20mm-φ2000mm.

We have established long term co-operation with a number of the world’s leading machine tool and robotics companies, the products can completely replace of INA/IKO/THK/FAG/SKF/KAYDON and other brands. We believe that cooperating with us will exceed your expectations.

- Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

- Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

- Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

- Robot Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

- Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

- Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF/ZARN Series);

- Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

- Hollow Rotary Platform Bearings ( ZK Series).

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty