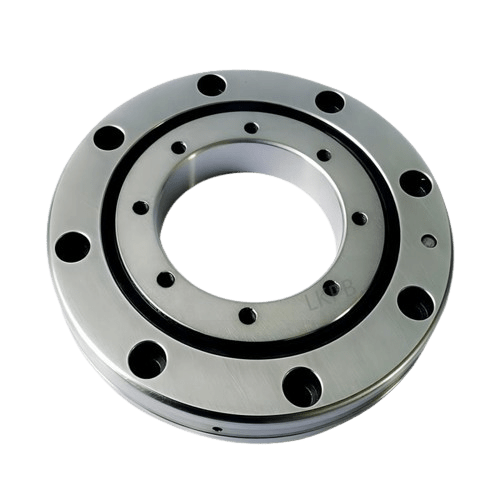

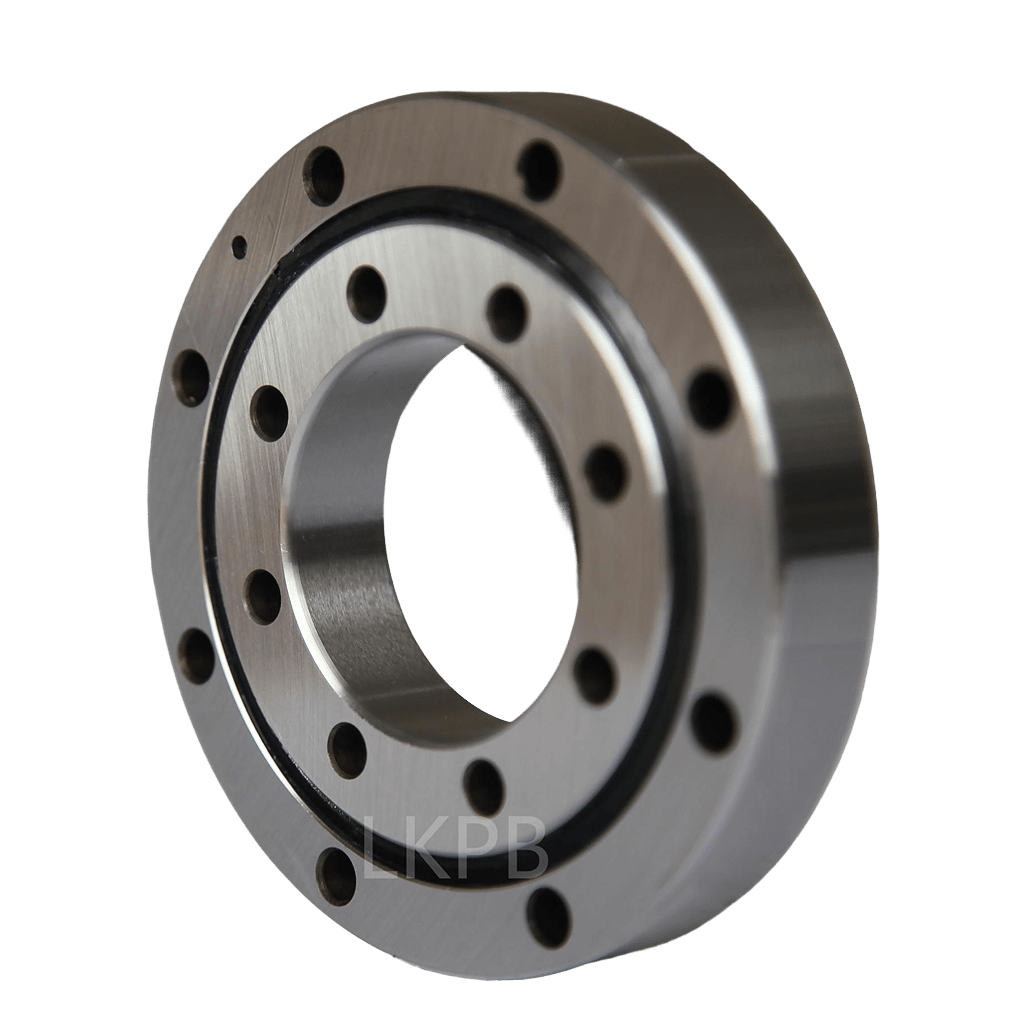

CSF/CSG Series Harmonic Reducer Bearings (split outer ring, integral inner ring)

The outer ring is divided into two pieces and the inner ring is a whole structure, which does not need flange and bearing seat when installing, and is mainly used in the output part of all kinds of reducers of CSG and CSF series.

Harmonic reducer bearings include rigid and flexible bearings, rigid bearings include four series, CSG (CSF) series, CSD series, SHG (SHF) series, and SHD series, whose nomenclature adopts the nomenclature of the harmonic reducer; Flexible Bearings include two series, F and 3E.

1. CSF/CSG Series Harmonic reducer bearings Structure

Rolling body is cylindrical roller, distributed in each other into 90 ° vertical arrangement in the V-type raceway. This structure makes a single bearing can simultaneously withstand axial load, radial load and tilting moment and other directions of load, the bearing has a high stiffness, rotational accuracy and composite bearing capacity; this type of bearings in compact shape, the bearings come with mounting holes, easy for customers to install directly, suitable for a variety of different types of harmonic reducer.

2. CSF/CSG Series Harmonic reducer bearings Features

CSF/CSG/SHF/SHG Series Cross Roller Bearing for Harmonic Drive is cross roller structure.According to its application area there are two types( CSF/CSG Series and SHF/SHG Series ).Rolling body are cylindrical rollers which arranged orthogonality,this structure can make one bearing can bear the load from every direction e.g. radial,axial and tilting torque etc. Bearing with high rigidity,rotation accurancy and load carrying capacity. This series bearing has compact appearance,with mounting hole,customer can mount directly,suitable for every kinds of harmonic drives.

3. CSF/CSG Series Harmonic reducer bearings pplications

Harmonic reducer is usually applied on rob9ts, machine tool, and aerospace industries which have higli requiremets on harmonic reducer precision7 rigidity, and load capacity. So it has high requirements -ts:

harmonic reducer parts machining precision rd mountng precision and also to bearings. For rigid bearing the most important are the bearing rigidity, reliability, and rotation precision. Rigid bearing usually has some prelad before leaving the factory in 94-der to giarantee bearing has enough rigidity. The maximum (radial defdrmation is very important to flexible bearing.)

5. CSF/CSG Series Harmonic reducer bearings Escription

| LKPB Model | Dimensions(mm) | |||||||||||||

| d | D | T | D1 | D2 | D21 | D3 | nl-dl | n2-d2 | n21-d21 | n3-d3 | d31 | t31 | rsmin | |

| CSF(CSG)14 | 9 | 55 | 16.5 | 49 | 23 | 14.5 | 15.5 | 8-φ3.5 | 6-M4 | 6-M3 | 2-φ3 | — | 0.3×45° | |

| CSF(CSG)17 | 10 | 2 | 16.5 | 56 | 27 | 17.5 | 17.5 | 10-φ3.5 | 6-M5 | 6-M4 | 2-φ3 | — | 0.3×45° | |

| CSF(CSG)20 | 14 | 70 | 16.5 | 64 | 32 | 24 | 19 | 12-φ3.5 | 8-M6 | 8-M5S | 4-φ3 | 4-φ2.8 | 7 | 0.3×45° |

| CSF(CSG)25 | 20 | 85 | 18.5 | 79 | 42 | 30 | 26 | 16-φ3.5 | 8-M8 | 8-M6 | 4-φ3 | 4-φ2.8 | 7 | 0.5×45° |

| CSF(CSG)32 | 26 | 112 | 22.5 | 104 | 55 | 40 | 34 | 16-φ4.5 | 8-M10 | 8-M8 | 4-φ5 | 4-φ4.7 | 10 | 0.5×45° |

| CSF(CSG)40 | 24 | 126 | 24 | 117 | 68 | 50 | 42 | 20-φ5 | 8-M10 | 8-M8 | 4-φ5 | — | 0.5×45° | |

| CSF(CSG)50 | 32 | 157 | 3l | 147 | 84 | 60 | 50 | 16-φ5.5 | 8-M14 | 8-M14 | 4-φ5 | — | 0.5×45° | |

| CSF(CSG)65 | 44 | 210 | 39 | 198 | 110 | 80 | 64 | 20-φ6.5 | 8-M16 | 8-M16 | 4-φ6 | — | 0.5×45° | |

| LKPB Model | Radial runout tolerancelaxial runout tolerance or inner ring | Internal radial clearance | Basic load rating | Weight | ||||||

| CCo | Co | KN | ||||||||

| P5 | P4 | P2 | Min | Max | Min | Max | Cr | Cor | kg | |

| CSF(CSG)14 | 4 | 3 | 2.5 | -10 | 0 | 0 | 20 | 4.6 | 5.1 | 0.25 |

| CSF(CSG)17 | 4 | 3 | 2.5 | -10 | 0 | 0 | 25 | 5.2 | 6.4 | 0.27 |

| CSF(CSG)20 | 4 | 3 | 2.5 | -10 | 0 | 0 | 25 | 6.1 | 8.4 | 0.36 |

| CSF(CSG)25 | 5 | 4 | 2.5 | -10 | 0 | 0 | 30 | 11.2 | 16 | 0.65 |

| CSF(CSG)32 | 5 | 4 | 2.5 | -10 | 0 | 0 | 35 | 18.5 | 28.3 | 1.1 |

| CSF(CSG)40 | 5 | 4 | 2.5 | -10 | 0 | 0 | 40 | 18.9 | 30.7 | 1.6 |

| CSF(CSG)50 | 5 | 4 | 2.5 | -10 | 0 | 0 | 40 | 42.8 | 67.7 | 3.6 |

| CSF(CSG)65 | 6 | 5 | 2.5 | -15 | 0 | 0 | 50 | 67.7 | 114.9 | 7.8 |

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Product precision can be P5, P4, P2 and VSP, Inside diameter size range φ20mm – φ2000mm. Maximum product quality warranty of 24 months, OEM acceptable.

LKPB With more than 10 years of production experience, The most professional suppliers of precision bearings in China.

Are your products reliable?

LKPB® strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective,

LKPB®, turning the world, carrying unlimited! We have served thousands of customers all over the world during the ten years of our establishment.

Our future goal is to become the most professional manufacturer of rotary table bearings and crossed roller bearings in China, and make LKPB® a world-class bearing brand.

This is our vision and direction!

Do you have export experience?

LKPB® has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

1. Precision Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series)

2. Precision Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

3. Precision Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

4. Robot Harmonic Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

5. Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

6. Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF, ZARN Series);

7. Precise Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

8. Hollow Rotary Platform Bearings ( ZK Series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time