Introduction to Slewing Ring Bearings

Slewing ring bearings, also known as slewing bearings or slewing rings, are essential components in various industrial applications that require precise rotational movement and the ability to support heavy radial and axial loads. These specialized bearings are designed to facilitate smooth, controlled rotation while withstanding extreme operating conditions. With their versatility and durability, slewing ring bearings have become indispensable in a wide range of industries, from construction and mining to renewable energy and industrial automation.

Choosing the right slewing ring bearing for your application is crucial for ensuring optimal performance, reliability, and cost-effectiveness. With so many options available in the market, it can be a daunting task to navigate the selection process. In this comprehensive guide, we’ll explore the key factors to consider when choosing a slewing ring bearing and highlight the expertise of LKPB, a leading slewing ring bearing manufacturer and supplier in China.

Understanding Your Application Requirements

Before delving into the selection process, it’s essential to have a thorough understanding of your application requirements. This includes factors such as:

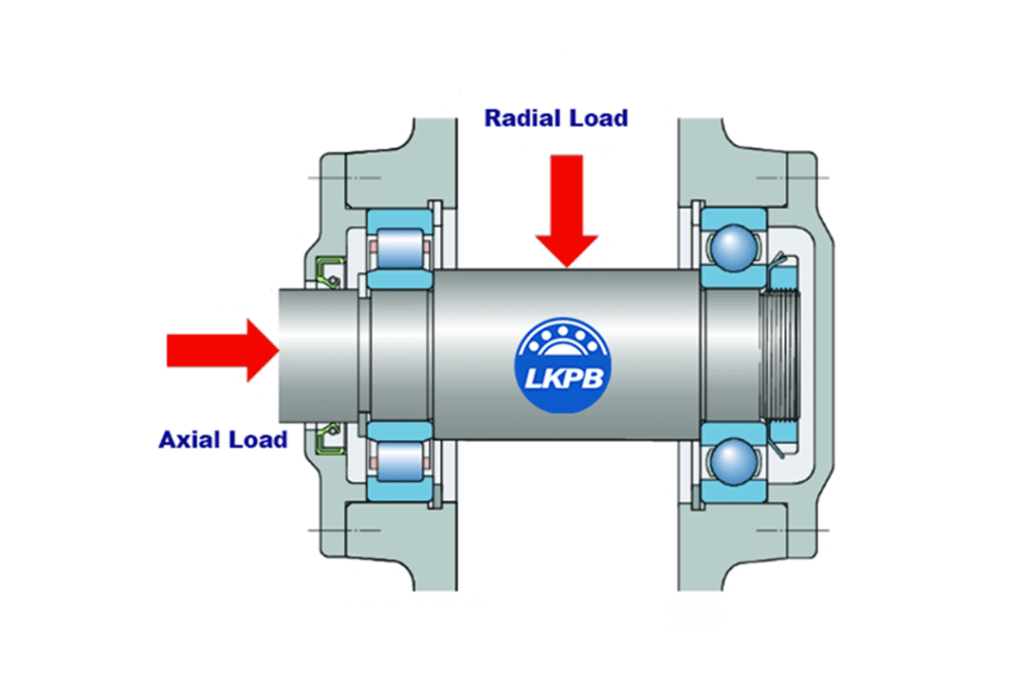

- Load Capacity: Determine the combined radial and axial loads that the slewing ring bearing will need to support, including static and dynamic loads.

- Operating Environment: Consider the environmental conditions in which the bearing will operate, such as temperature, humidity, exposure to contaminants, and potential shock or vibration loads.

- Rotational Speed and Accuracy: Evaluate the required rotational speed and positioning accuracy for your application.

- Service Life and Maintenance: Assess the desired service life of the bearing and the maintenance requirements, including lubrication and inspection intervals.

- Size and Space Constraints: Understand the available space and dimensional constraints for integrating the slewing ring bearing into your equipment or machinery.

By clearly defining these requirements, you’ll be better equipped to select a slewing ring bearing that meets the demands of your specific application.

Factors to Consider When Choosing a Slewing Ring Bearing

Once you have a solid understanding of your application requirements, consider the following factors when selecting a slewing ring bearing:

- Load Capacity: Ensure that the slewing ring bearing you choose has a sufficient load rating to handle the combined radial and axial loads in your application, with an appropriate safety factor.

- Operating Environment Suitability: Select a bearing designed to withstand the environmental conditions of your application, including temperature, humidity, and potential contaminants. Specialized sealing and lubrication options may be required for harsh environments.

- Precision and Rigidity: Evaluate the precision and rigidity of the slewing ring bearing to ensure it meets the required positioning accuracy and minimizes deflection under load.

- Rotational Speed Capability: Choose a bearing designed for the rotational speed range of your application, considering both low-speed and high-speed requirements.

- Materials and Surface Treatments: Consider the material composition and surface treatments of the bearing components to ensure durability, corrosion resistance, and wear resistance specific to your application.

- Customization and Design Flexibility: Assess the supplier’s ability to provide customized solutions, including design modifications, material selections, and specialized coatings, to meet your unique requirements.

- Supplier Reputation and Support: Evaluate the supplier’s reputation, manufacturing capabilities, quality control processes, and customer support services to ensure a reliable and long-term partnership.

The LKPB Advantage: Customizable and High-Quality Slewing Ring Bearings

LKPB, a renowned slewing ring bearing manufacturer and supplier in China, stands out as a trusted partner for customizable and high-quality slewing ring bearing solutions. With a state-of-the-art factory and skilled workforce, LKPB is dedicated to delivering innovative solutions that meet the diverse needs of its global customers.

One of the key advantages of partnering with LKPB is their commitment to customization and OEM services. The company’s engineering team works closely with clients to design and manufacture slewing ring bearings that meet their exact specifications, ensuring optimal performance and reliability in even the most demanding applications.

In addition to custom solutions, LKPB also provides OEM (Original Equipment Manufacturer) services, partnering with manufacturers to integrate their slewing ring bearings seamlessly into their products.

Quality and Reliability: The LKPB Advantage

LKPB is committed to delivering products of the highest quality and reliability. Their advanced manufacturing processes, strict quality control measures, and adherence to international standards ensure that every slewing ring bearing meets or exceeds industry benchmarks.

They use premium raw materials and implement rigorous testing procedures to guarantee the durability and performance of their slewing ring bearings. LKPB’s team of experienced engineers and technicians is dedicated to providing exceptional customer service and technical support throughout the entire product lifecycle.

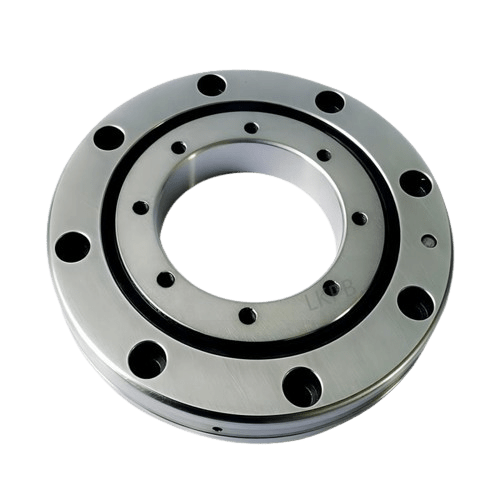

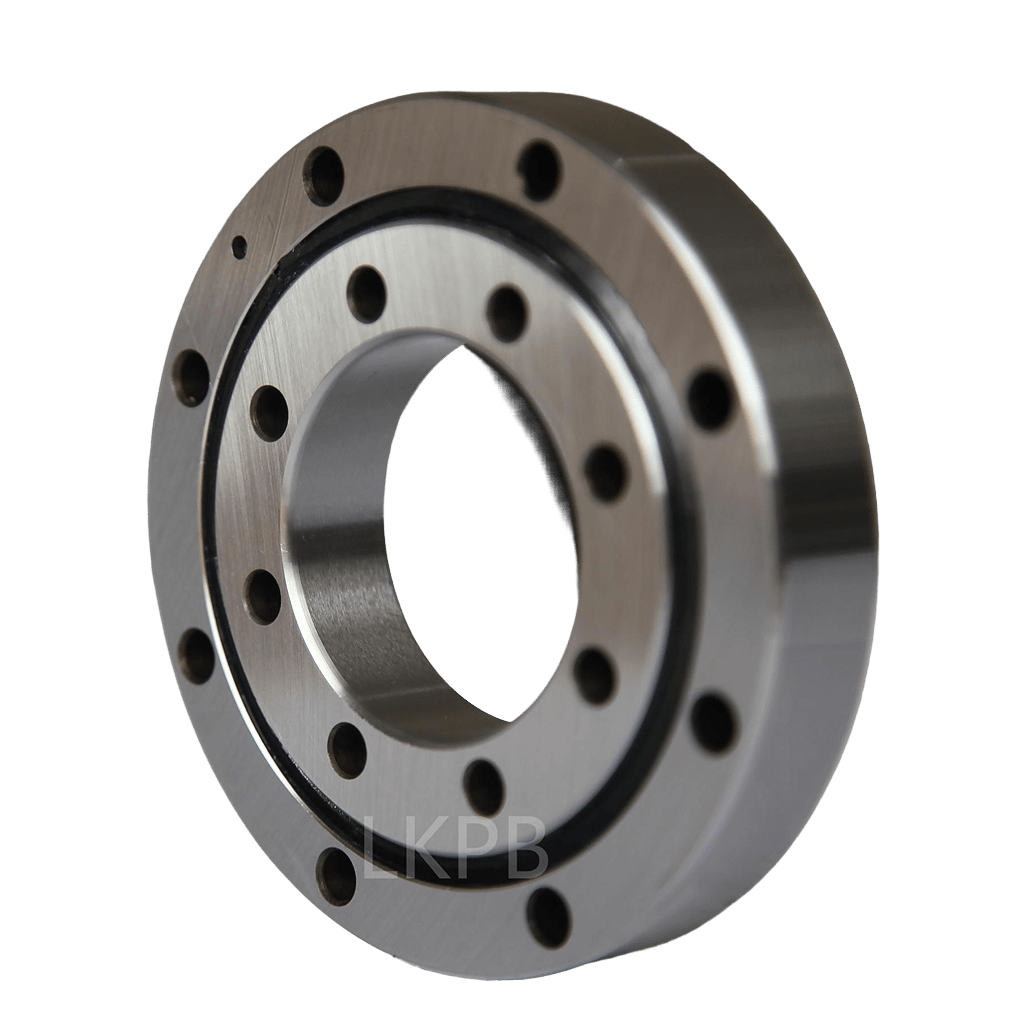

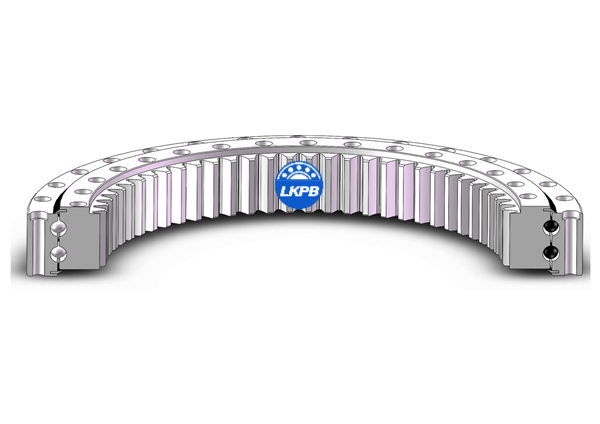

LKPB Slewing Ring Bearing products

Conclusion

Choosing the right slewing ring bearing for your application is crucial for ensuring optimal performance, reliability, and cost-effectiveness. By thoroughly understanding your application requirements and carefully evaluating factors such as load capacity, operating environment, precision, and customization options, you can make an informed decision that meets the specific needs of your project.

LKPB, a leading slewing ring bearing manufacturer and supplier in China, stands out as a trusted partner offering customizable and high-quality solutions. With their commitment to innovation, quality, and customer service, LKPB is well-equipped to help you navigate the selection process and find the ideal slewing ring bearing for your application.

Remember, investing in the right slewing ring bearing can significantly enhance the performance, longevity, and safety of your equipment or machinery, ultimately contributing to increased productivity and a competitive edge in your industry.

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Product precision can be P5, P4, P2 and VSP, Inside diameter size range φ20mm – φ2000mm. Maximum product quality warranty of 24 months, OEM acceptable.

LKPB With more than 10 years of production experience, The most professional suppliers of precision bearings in China.

Are your products reliable?

LKPB® strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective,

LKPB®, turning the world, carrying unlimited! We have served thousands of customers all over the world during the ten years of our establishment.

Our future goal is to become the most professional manufacturer of rotary table bearings and crossed roller bearings in China, and make LKPB® a world-class bearing brand.

This is our vision and direction!

Do you have export experience?

LKPB® has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

1. Precision Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series)

2. Precision Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

3. Precision Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

4. Robot Harmonic Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

5. Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

6. Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF, ZARN Series);

7. Precise Slewing Bearring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

8. Hollow Rotary Platform Bearings ( ZK Series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time