Welcome to our comprehensive guide on thin section bearings – the compact yet powerful components that drive precision machinery across industries. In this article, we’ll delve into the unique features, applications, benefits, and considerations of thin section bearings.

What are Thin Section Bearings?

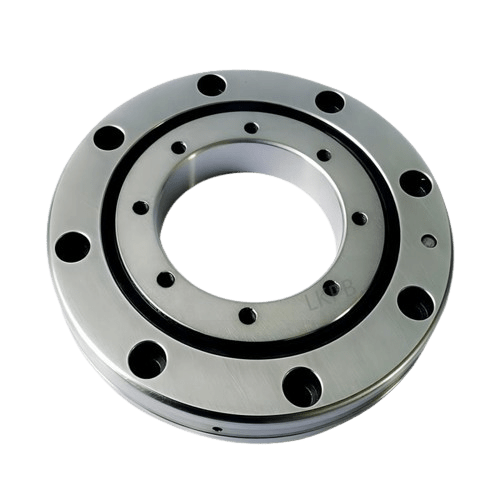

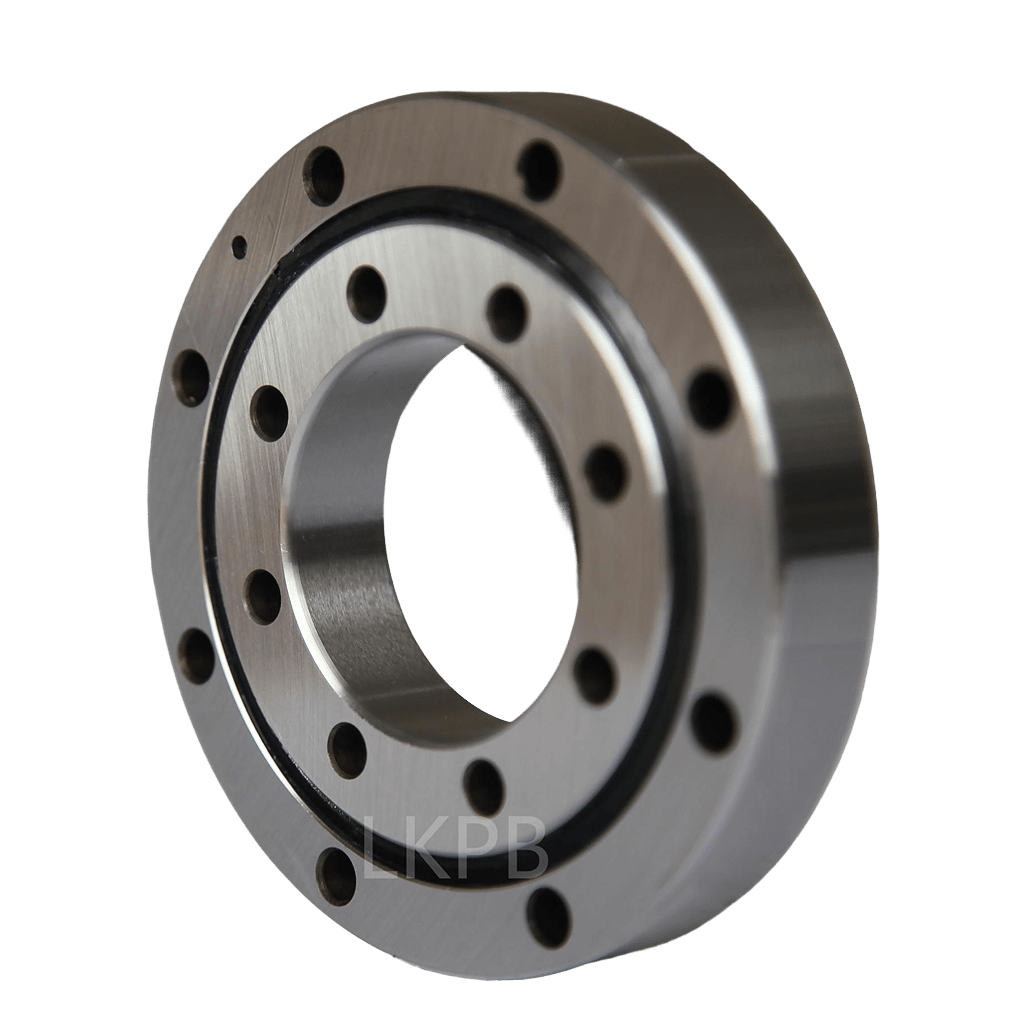

Thin section bearings, also known as slim bearings or slim ball bearings, are specialized components engineered for applications where space is at a premium. These bearings are designed with incredibly thin rings, enabling them to fit into tight spaces without compromising performance.

Thin Section Bearings Key Features and Benefits:

- Space Efficiency: Discover how the slim profile of thin section bearings maximizes available space within machinery, making them ideal for compact designs.

- Precision Performance: Learn how the precision manufacturing of these bearings results in smooth operation and accurate motion control.

- Load Distribution: Explore how thin section bearings evenly distribute loads, ensuring optimal performance under various conditions.

- Versatile Applications: Discuss the wide range of industries that benefit from thin section bearings, including robotics, medical devices, aerospace, and more.

Applications of Thin Section Bearings:

Thin section bearings find their applications in various industries and equipment, including:

- Robotics and Automation: Discuss how these bearings contribute to the precise movements of robotic arms and joints, enhancing automation processes.

- Aerospace: Highlight the role of thin section bearings in aviation systems where weight and space savings are critical.

- Medical Devices: Explain their usage in medical equipment such as imaging devices, where precision is paramount.

- Industrial Machinery: Explore how these bearings support the efficiency of industrial machines, conveyors, and more.

Factors to Consider When Choosing Thin Section Bearings:

- Load Capacity: Explain how the load-bearing capacity of thin section bearings depends on factors such as bearing type, material, and design.

- Rigidity and Clearance: Discuss the importance of selecting the right level of rigidity and clearance to meet specific application requirements.

- Material Selection: Detail the options available, such as stainless steel or chrome steel, and their suitability for different environments.

- Lubrication: Emphasize the significance of proper lubrication in maintaining the longevity and performance of thin section bearings.

LKPB Thin Section Bearings Products:

KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU series

Open Type Radial Contact Ball (Type C)

Open Type Four Point Contact Ball (Type X)

Open Type Angular Contact Ball (Type A)

Thin Section Bearings Maintenance and Installation Tips:

- Installation Guidelines: Provide step-by-step instructions for proper bearing installation to prevent premature wear and damage.

- Lubrication Schedule: Recommend a lubrication schedule to keep the bearings operating smoothly and extend their service life.

- Monitoring and Inspection: Suggest regular monitoring and inspection routines to catch any potential issues before they escalate.

Conclusion:

In conclusion, thin section bearings are indispensable components for applications demanding precision and efficiency within minimal space. Their unique design, coupled with the advantages they offer, makes them a smart choice for various industries. Whether it’s enhancing robotics, aerospace, medical devices, or industrial machinery, thin section bearings are at the forefront of driving technological advancements.

For expert guidance on selecting the right thin section bearings for your specific needs, feel free to contact our knowledgeable team. Discover how our precision solutions can optimize your machinery’s performance and efficiency. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Product comes with 24 months warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

Our Customer Testimonials

We enjoy doing business with LKPB because they are predictable. Our company mainly purchases YRT bearings. Being able to predict deliveries before ordering and knowing your delivery time is a big plus.

LKPB’s website is easy to navigate and to compare with other manufacturers. … They have an awesome customer service team that is always happy to help. Returns are always easy—saving time and hassle. Working with LKPB in 2018 has saved our company Time, Money, and Sanity.

Good bearings, there are practically no backdoors. Believe me, I know what I'm talking about. But as practice will show. I'll add a tip. Shipping fast.

Ordered harmonic speed reducer bearings, came up perfectly as native, no complaints, I recommend, the price is a fairy tale