Investing in slewing bearings is a major expense for industrial equipment. Prices can range from a few thousand dollars for smaller units to over $100,000 for large diameter rings. With such a wide variance, it’s important to understand the key cost factors involved. In this guide, we’ll break down the primary elements that impact slewing bearing pricing.

Slewing Ring Size and Dimensions

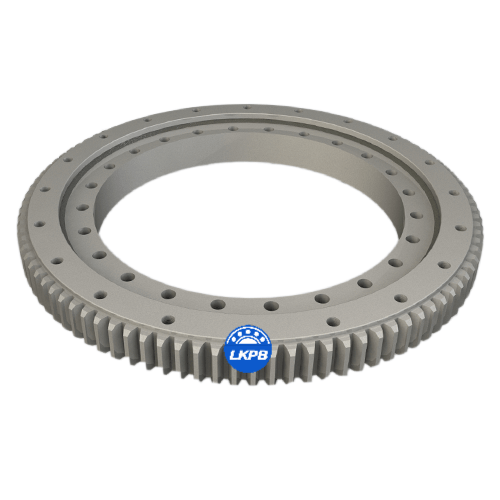

Size is the biggest single pricing factor for slewing rings. Larger diameters and cross-sections require exponentially more materials and manufacturing effort. However, dimensions alone don’t tell the full story…

Bearing Type and Internal Design

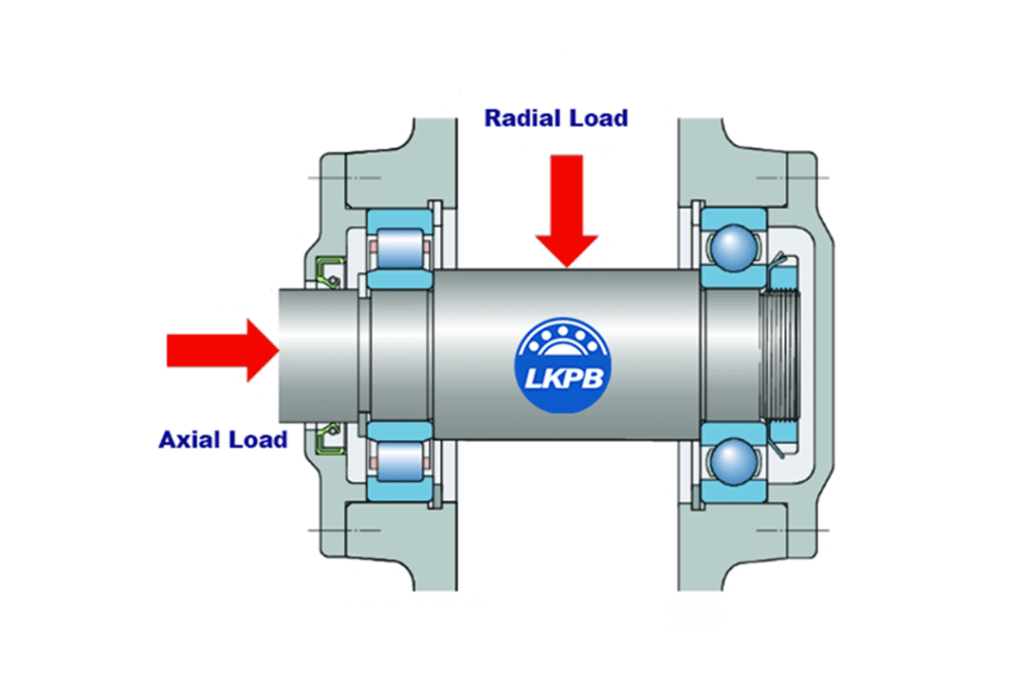

Different bearing types like three-row roller, four-point contact ball, or crossed roller have varying designs that affect complexity and cost. The internal geometry of raceways, ball/roller configurations, and sealing approach all impact pricing.

Materials and Heat Treating

The choice of materials is critical for durability, load capacities, and operating conditions. Common materials like nylon, brass, or chrome steel are affordable, while stainless steel or specialty alloys drive up costs. Heat treatment is also a significant component.

Precision and Tolerances

Precision manufacturing requirements like tight tolerances, surface finishes, and runout specifications increase production complexity and costs. Applications with high speeds or load requirements generally necessitate higher precision grades.

Mounting and Installation

An often-overlooked pricing factor is how slewing rings integrate into the equipment design. Special mounting features, gearing attachments, and accessibility for installation all influence complexity and pricing.

Made in China vs. Western Suppliers

Manufacturing location also impacts pricing. Slewing bearings produced by Western suppliers in Europe or North America tend to be 30-50% higher versus equivalent China-manufactured products like those from LKPB.

Understanding LKPB’s Cost-Effective Solutions

As a leading slewing bearing manufacturer in China, LKPB Bearing provides high-quality yet affordable solutions, even for custom OEM products. Their capabilities include:

- Slewing rings from 200mm up to 6.5m diameter

- Fully customizable slewing ring engineering and manufacturing

- Fast turnarounds – 15 days for standard products, 4-6 weeks for customs

- Comprehensive services – applications, installation, service/repair, etc.

- Specialty offerings like flip chip resistant coatings

By taking advantage of LKPB’s China-based production and expertise, you can procure high-performance slewing rings at 30-50% below pricing from Western suppliers. Their team works closely with each customer to optimize designs and manufacturing to meet your target pricing goals.

Price vs. Total Cost of Ownership

While upfront pricing is important, it’s also critical to consider the bearing’s total cost of ownership, including operating costs and service life. Higher quality bearings may be more expensive upfront but could deliver far lower lifetime costs through increased uptime, reliability, and longevity. Factoring in factors like lead times, availability, and supplier services is also wise.

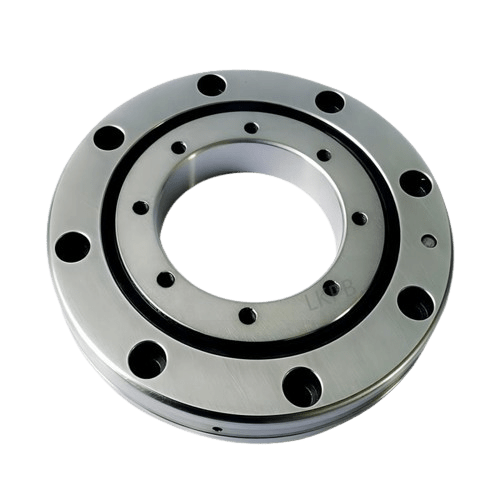

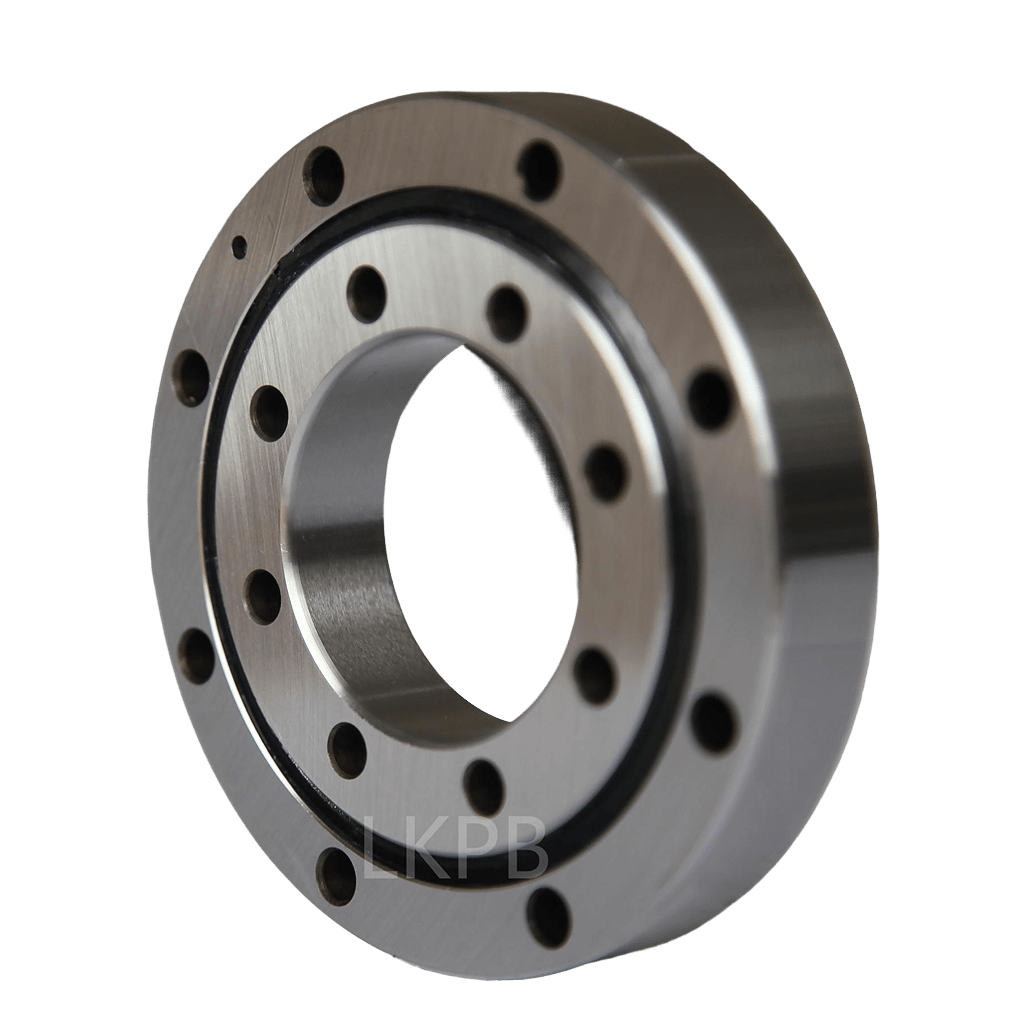

LKPB's Slewing Bearing

LKPB: The Ideal Pricing Partner for Your Needs

Whether you need standard, customized or drop-in replacement slewing rings for INA or other brands, LKPB has the experience to deliver a cost-effective solution optimized for your application. They provide comprehensive technical consultation and rapid turnaround times.

To learn more about how LKPB Bearing can meet your slewing ring requirements at the right pricing, contact their team today for a free consultation and quotation. Their experts will be happy to discuss your project details and pricing objectives.

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Product precision can be P5, P4, P2 and VSP, Inside diameter size range φ20mm – φ2000mm. Maximum product quality warranty of 24 months, OEM acceptable.

LKPB With more than 10 years of production experience, The most professional suppliers of precision bearings in China.

Are your products reliable?

LKPB® strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective,

LKPB®, turning the world, carrying unlimited! We have served thousands of customers all over the world during the ten years of our establishment.

Our future goal is to become the most professional manufacturer of rotary table bearings and crossed roller bearings in China, and make LKPB® a world-class bearing brand.

This is our vision and direction!

Do you have export experience?

LKPB® has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

1. Precision Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series)

2. Precision Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

3. Precision Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

4. Robot Harmonic Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

5. Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

6. Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF, ZARN Series);

7. Precise Slewing Bearring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

8. Hollow Rotary Platform Bearings ( ZK Series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time