LKPB is precision rotary table bearings manufacturer from China, we have more than 10 years of production experience, our products are exported to more than 120 countries, we have a strong technical team, we can accept the customized production of non-standard rotary table bearings, you can contact us if you have any needs!

Rotary table bearings are essential components in a variety of applications, ranging from robotics to medical equipment. They are designed to support loads and provide precise indexing in applications that require complex, rotational movements. This in-depth guide will explore the fundamentals of rotary table bearings, their uses, selection, maintenance, and more.

Introduction to Rotary Table Bearings

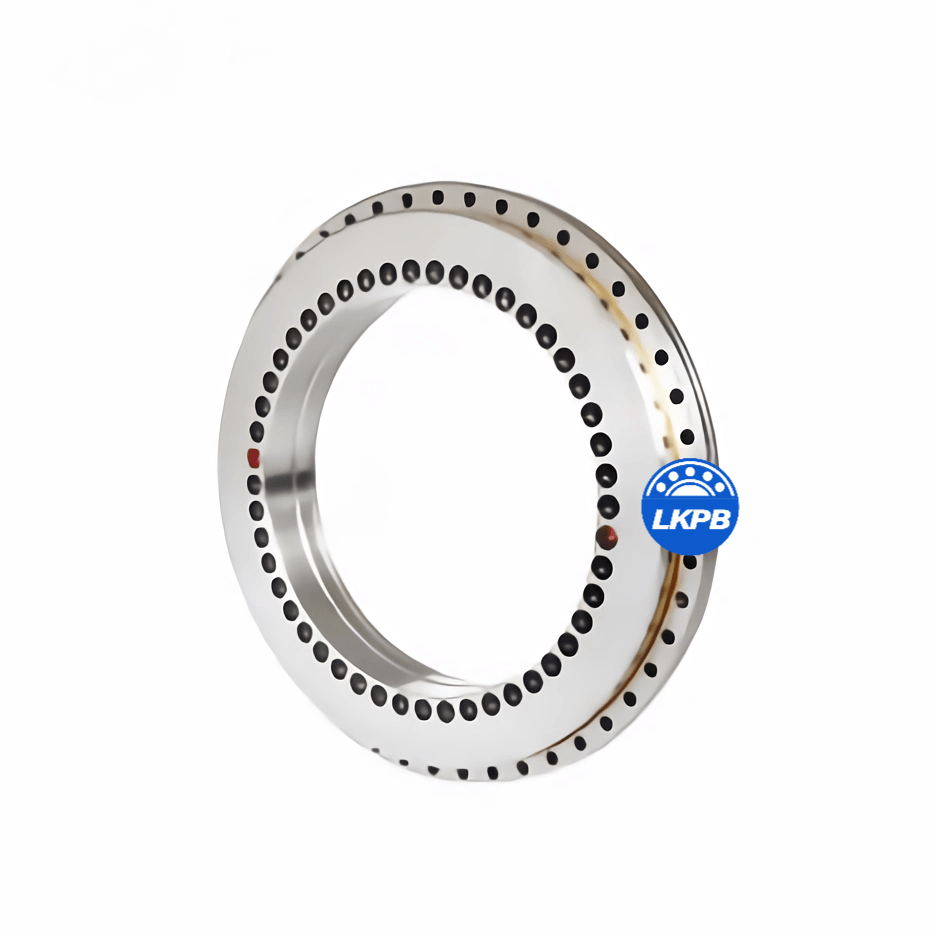

Rotary table bearings, also known as slewing ring bearings, are large bearings designed to handle complex load transmissions. Typically, they are made of two concentric rings with rolling elements in between – these could be balls or cylindrical rollers. The outer ring is often segmented, allowing it to support large radial, axial, or moment loads.

Types of Rotary Table Bearings

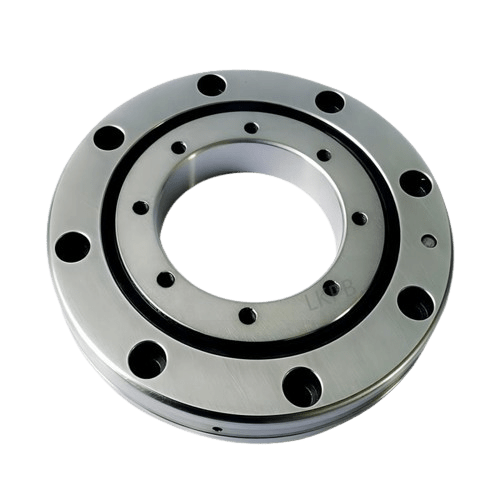

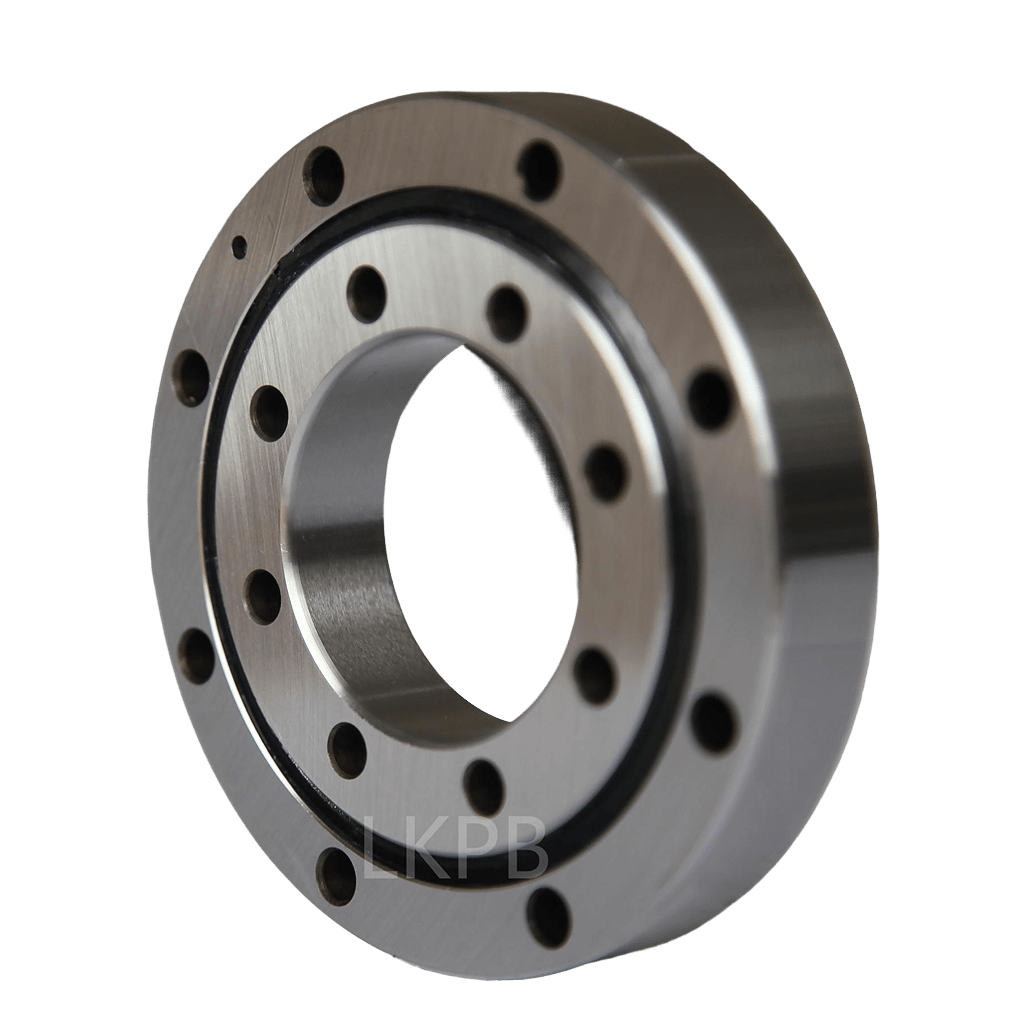

1. YRT Rotary Table Bearings

YRT Rotary Table Bearing can be used to the machine tool and other high precision machinery of the rotary table or sub-set, and also can be used for chuck, measuring instruments and test equipment and rotary table configuration, this bearing requires higher quality of the parts to match it. you can control screw tightening torque when install it.

2. YRTS High Speed Rotary Table Bearings

YRTS (YRT Speed) high-speed rotary table bearings are a specialized type of rotary table bearing designed to meet the demands of applications requiring both high precision and rapid rotational speeds. These bearings are known for their exceptional performance characteristics, making them suitable for a range of applications in various industries. Here are some common applications for YRTS high-speed rotary table bearings: Machine Tools and CNC Machining Centers; Robotic Arms and Automation; Medical Equipment; Semiconductor Manufacturing; Aerospace and Defense.

3. YRTM With Integrated Angle Measuring System Rotary Table Bearings

This series of bearings is based on YRT rotary table bearings. An angular measurement system is installed on the YRT to accurately measure and adjust the rotation angle of the bearing. The precision can reach ±1 arc-second. It is suitable for applications which need high requirements for the angle positioning accuracy.

4. ZKLDF Axial Angular Contact Ball Bearings

ZKLDF Axial angular contact ball bearings are particularly suitable for precision applications involving combined loads. Their preferred areas of use are bearing arrangements in rotary tables with a main spindle function, for example in combined milling and turning, as well as in milling, grinding and honing heads and in measurement and testing equipment.

Applications Of Rotary Table Bearings

1. Industrial Automation

In industries such as automotive manufacturing, rotary table bearings are used in robotic arms for assembling parts. Their ability to handle complex loads and rotate precisely makes them ideal for these applications.

2. Medical Equipment

In medical applications, rotary table bearings are used in devices like CT scanners that need to rotate around the patient with high precision. They also find use in robotic surgery systems.

3. Wind Turbines

In wind turbines, rotary table bearings are used to allow the turbine blades to rotate smoothly in the wind. They must be robust and durable, as they often operate in harsh conditions.

Selecting The Right Rotary Table Bearings

Choosing the right rotary table bearing depends on several factors, including the nature of the load, the required precision, the speed of rotation, and the operational environment.

1. Load Capacity

Consider the loads the bearing will need to handle. This includes radial loads (perpendicular to the axis of rotation), axial loads (along the axis of rotation), and moment loads (causing rotation).

2. Precision

The required precision depends on the application. For example, robotic surgery requires very high precision, while some industrial applications may not.

3. Speed

Higher speeds generally require bearings with lower friction, such as ball bearings. For lower speeds or stop-start operation, roller bearings may be more appropriate.

4. Environment

The operational environment affects the bearing selection. For example, in a corrosive environment, stainless steel bearings may be needed.

Maintenance And Troubleshooting Of Rotary Table Bearings

Regular maintenance is crucial to ensure the longevity of rotary table bearings. This can include regular lubrication, monitoring for signs of wear, and timely replacement of worn-out parts.

Troubleshooting common problems can involve checking for excessive noise, which may indicate a lack of lubrication or worn-out elements. Unusual movement might suggest misalignment or an uneven load distribution.

Future Trends In Rotary Table Bearings

With advancements in technology, we can expect further improvements in rotary table bearings. These might include new materials for increased durability, better designs for higher load capacities, and smart bearings that can monitor their own condition and alert users to potential problems.

LKPB Rotary Table Bearings Products

LKPB Rotary Table Bearings test video

LKPB rotary table bearing related news

Innovative Applications of Needle Roller Bearings in 2024

The Importance of Needle Roller Bearings Needle roller bearings are specialized components that offer unique advantages in terms of load-carrying

Essential Facts About Axial Bearing Thrust Bearings

Understanding Axial Bearing Thrust Bearings Axial bearing thrust bearings are specialized components designed to withstand axial loads, facilitating smooth and

The Evolution of Axial Bearing Roller Bearings: A Comprehensive Guide

Understanding Axial Bearing Roller Bearings Axial bearing roller bearings are specialized components designed to withstand axial loads, ensuring smooth and

A Comprehensive Guide to the Classification of Bearings in 2024

LKPB: A Leading Bearing Manufacturer in China As a renowned bearing manufacturer and factory in China, LKPB has established itself

The Ultimate Guide to Wheel Bearings Maintenance in 2024

Proper wheel bearing maintenance is crucial for vehicle safety, performance, and longevity. As we look ahead to 2024, advances in

Essential Bearings Every Mechanic Should Know About in 2024

Top Bearing Suppliers, Manufacturers in China: Company Services, Prices, Customizable OEM Options Bearings are critical components in all kinds of

About LKPB Bearing Company

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional bearing manufacturer.

LKPB strictly follows the ISO9001 quality system requirements for product quality control, we have a strong technical team to accept processing of non-standard precision bearings of P5, P4, P2 and VSP level of accuracy. The products inner diameter size range is φ20mm-φ2000mm.

We have established long term co-operation with a number of the world’s leading machine tool and robotics companies, the products can completely replace of INA/IKO/THK/FAG/SKF/KAYDON and other brands. We believe that cooperating with us will exceed your expectations.

- Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

- Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

- Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

- Robot Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

- Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

- Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF/ZARN Series);

- Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

- Hollow Rotary Platform Bearings ( ZK Series).

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty