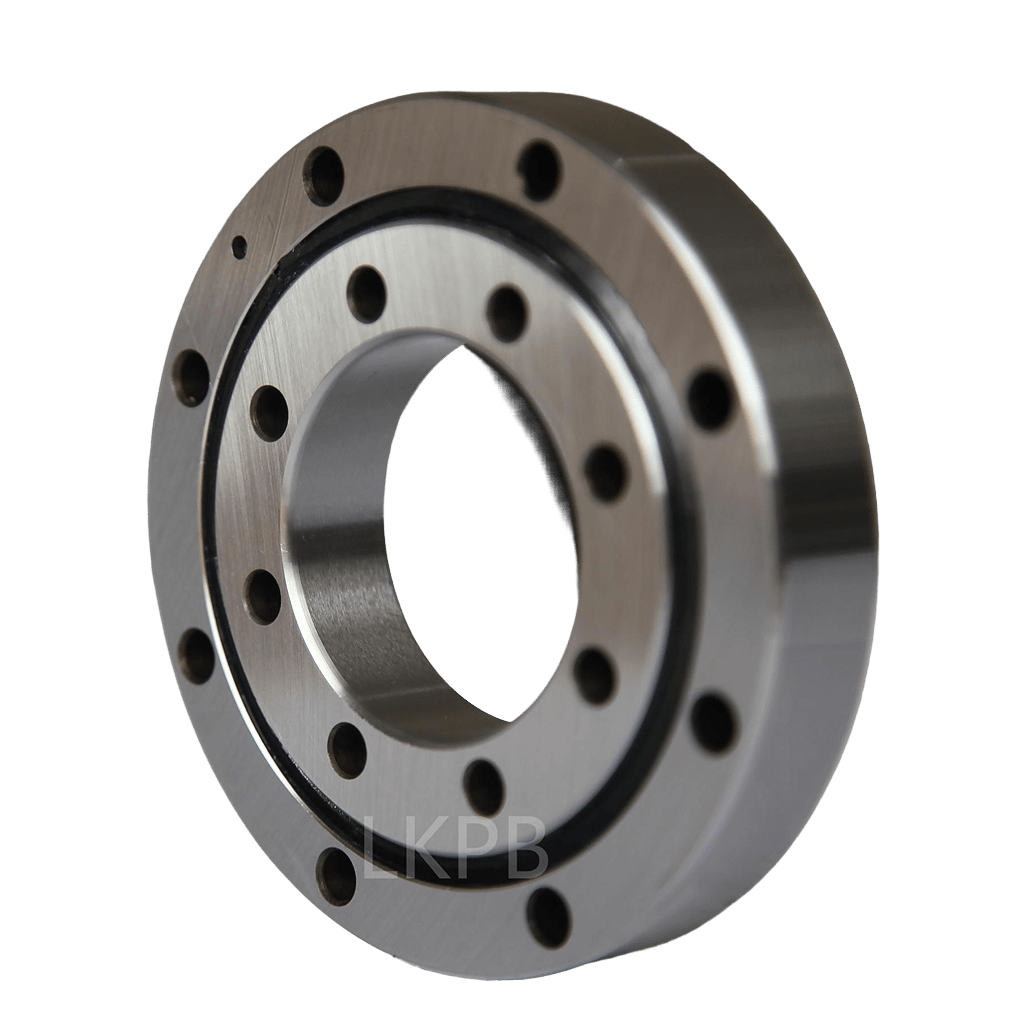

LKPB is the most specialized cross roller beaings manufacturer, We have rich production experience and professional technical team, Can support bearing customization,Please contact us for any of your needs.

What is a cross roller bearings?

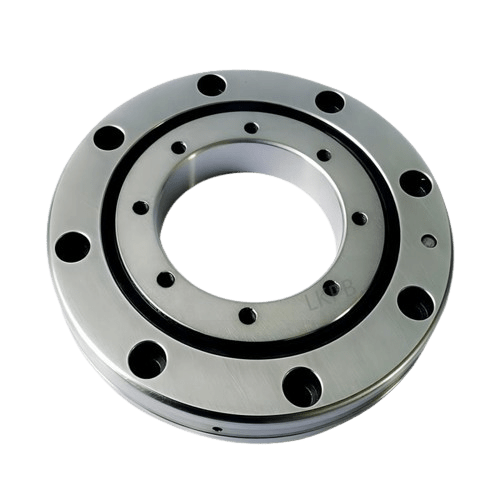

A cross roller bearings is a type of rolling-element bearing that is designed to provide high precision and rigidity in a compact package. It consists of two sets of cylindrical rollers that are arranged in a crossed pattern and separated by a cage or spacer. The rollers are oriented at right angles to each other and are held in place by the cage, which prevents them from contacting each other. This design allows the bearing to support loads from all directions, making it ideal for applications that require high precision and stiffness.

How does a cross roller bearings work?

When a load is applied to a crossed roller bearings, the rollers rotate around their own axes and move along the raceways of the bearing. Because the rollers are arranged in a crossed pattern, they are able to support loads from all directions without any significant deformation. This results in a high degree of stiffness and precision in the bearing.

What are the benefits of using a cross roller bearings?

There are several benefits to using a cross roller bearings, including:

- High precision: Crossed roller bearings are designed to provide high levels of accuracy and repeatability in applications that require precise positioning and motion control.

- High rigidity: The crossed roller bearings design provides high levels of stiffness and rigidity, which makes it ideal for applications that require high loads and minimal deflection.

- Compact size: Crossed roller bearings have a relatively small footprint compared to other types of bearings, which makes them ideal for applications where space is limited.

- Low friction: The roller-to-raceway contact in a crossed roller bearing results in low friction and minimal wear, which helps to extend the life of the bearing.

What are some common applications of cross roller bearings?

Cross roller bearings are used in a variety of applications that require high precision and rigidity, including:

Robotics: Crossed roller bearings are often used in robotic arms and other precision robotics applications where high levels of accuracy and repeatability are required.

Machine tools: Crossed roller bearings are commonly used in machine tool applications such as milling machines, lathes, and grinders.

Medical equipment: Crossed roller bearings are used in medical equipment such as CT scanners and MRI machines, where precision and accuracy are critical.

Aerospace and defense: Crossed roller bearings are used in aerospace and defense applications where high precision and reliability are required.

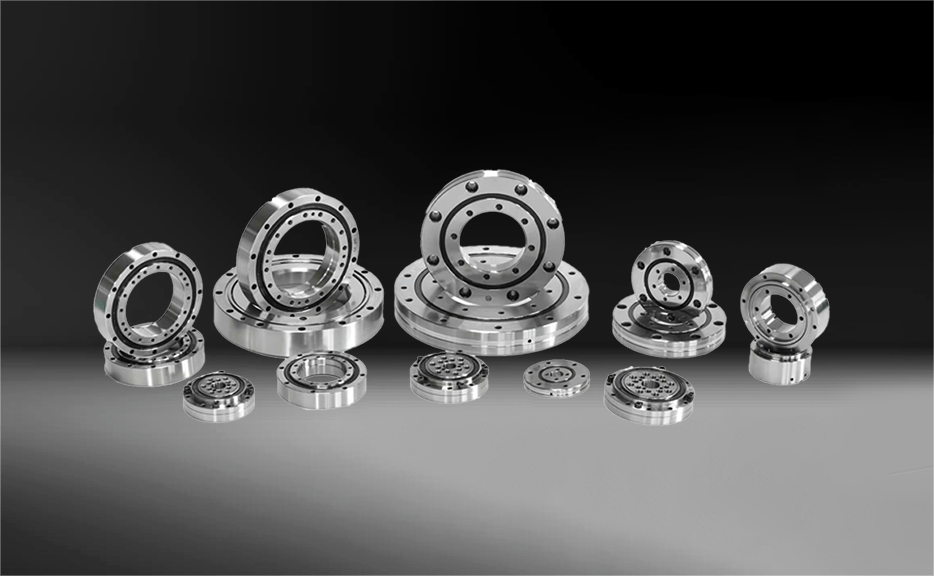

What types of cross roller bearings are available?

There are several types of cross roller bearings available, including:

Standard crossed roller bearings: These bearings have a standard design and are suitable for most applications that require high precision and rigidity.

Integrated inner/outer ring type: These bearings have integrated inner and outer rings, which simplifies the installation process and reduces the number of parts required.

Separable outer ring type: These bearings have a separable outer ring, which makes it easier to install and replace the bearing without having to remove other components.

High-speed type: These bearings are designed for high-speed applications where low friction and minimal heat generation are required.

How do you choose the right cross roller bearings for your application?

Choosing the right crossed roller bearings for your application can be challenging, as there are many factors to consider. Here are some key considerations:

Load capacity: Crossed roller bearings come in a range of load capacities, so it’s important to choose a bearing that can handle the load requirements of your application.

Accuracy: The level of precision required for your application will depend on factors such as the type of motion control you need and the degree of positional accuracy required.

Operating conditions: Consider the operating temperature range, speed, and environmental conditions that the bearing will be exposed to, as these factors can affect the performance and lifespan of the bearing.

Size: Crossed roller bearings come in a range of sizes, so it’s important to choose a bearing that fits the available space in your application.

Cost: Crossed roller bearings can vary in price depending on factors such as size, accuracy, and load capacity, so it’s important to consider the cost-effectiveness of different options.

What are some best practices for maintaining and caring for cross roller bearings?

To ensure the optimal performance and lifespan of your crossed roller bearings, it’s important to follow some best practices for maintenance and care. Here are some tips:

Regular cleaning: Keep the bearing clean and free from dirt and debris by regularly wiping it down with a clean cloth.

Lubrication: Ensure that the bearing is properly lubricated according to the manufacturer’s recommendations to prevent friction and wear.

Proper installation: Ensure that the bearing is installed correctly and securely, and that any necessary adjustments are made to ensure proper alignment.

Regular inspection: Regularly inspect the bearing for signs of wear, damage, or other issues that could affect its performance.

Replacement: If the bearing shows signs of wear or damage, it should be replaced promptly to prevent further damage to the bearing or other components of the system.

LKPB Cross Roller Bearings Product Categories:

LKPB Cross Roller Bearings Product Testing:

LKPB Cross Roller Bearings related news

Innovative Applications of Needle Roller Bearings in 2024

The Importance of Needle Roller Bearings Needle roller bearings are specialized components that offer unique advantages in terms of load-carrying

Essential Facts About Axial Bearing Thrust Bearings

Understanding Axial Bearing Thrust Bearings Axial bearing thrust bearings are specialized components designed to withstand axial loads, facilitating smooth and

The Evolution of Axial Bearing Roller Bearings: A Comprehensive Guide

Understanding Axial Bearing Roller Bearings Axial bearing roller bearings are specialized components designed to withstand axial loads, ensuring smooth and

A Comprehensive Guide to the Classification of Bearings in 2024

LKPB: A Leading Bearing Manufacturer in China As a renowned bearing manufacturer and factory in China, LKPB has established itself

The Ultimate Guide to Wheel Bearings Maintenance in 2024

Proper wheel bearing maintenance is crucial for vehicle safety, performance, and longevity. As we look ahead to 2024, advances in

Essential Bearings Every Mechanic Should Know About in 2024

Top Bearing Suppliers, Manufacturers in China: Company Services, Prices, Customizable OEM Options Bearings are critical components in all kinds of

About LKPB Bearing Company

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional bearing manufacturer.

LKPB strictly follows the ISO9001 quality system requirements for product quality control, we have a strong technical team to accept processing of non-standard precision bearings of P5, P4, P2 and VSP level of accuracy. The products inner diameter size range is φ20mm-φ2000mm.

We have established long term co-operation with a number of the world’s leading machine tool and robotics companies, the products can completely replace of INA/IKO/THK/FAG/SKF/KAYDON and other brands. We believe that cooperating with us will exceed your expectations.

- Rotary Table Bearings ( YRT, YRTC, YRTS, YRTM, ZKLDF Series) ;

- Cross Roller Bearings ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF Series);

- Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU Series);

- Robot Reducer Bearings (CSF/CSG, SHF/SHG, CSD Series, RV Reducer Bearings and Flexible Bearings F, 3E Series);

- Angular Contact Ball Bearings ( 718, 719, 70, 72, 2344/2347 Series);

- Ball Screw Support Bearings ( ZKLF/ZKLN, ZARF/ZARN Series);

- Slewing Ring ( Cross Roller, Four-Point Contact, Eight-Point Contact Same Path, Eight-Point Contact Different Path, Three-row roller and Flanged Series);

- Hollow Rotary Platform Bearings ( ZK Series).

For expert guidance in meeting your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Maximum 24 months product warranty