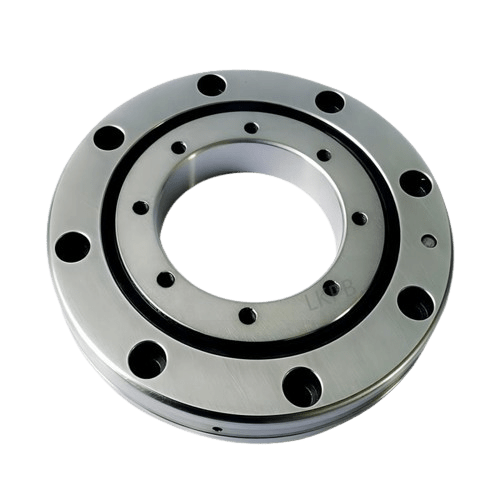

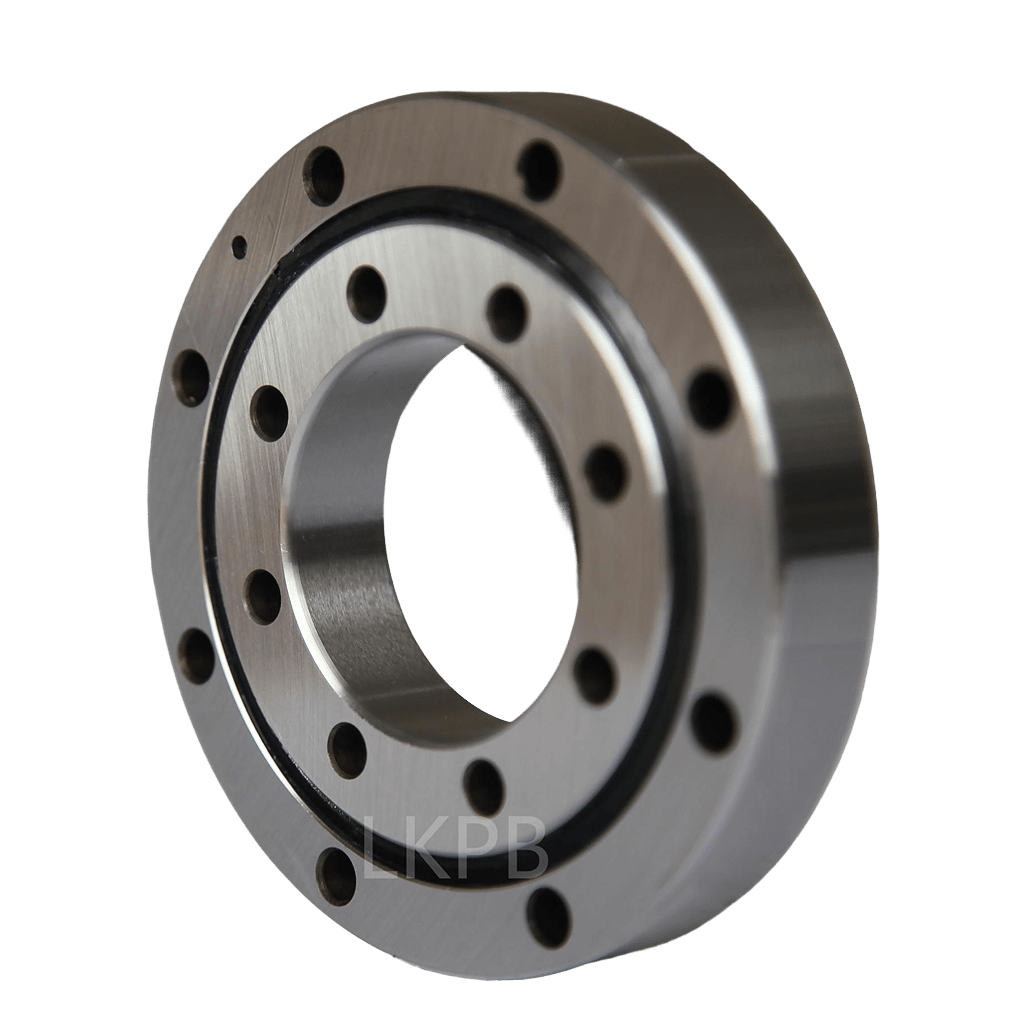

KAA series open type deep groove ball thin section bearings that can accommodate high speeds and heavy loads. They consist of an inner and outer race with a cage that separates the balls evenly around the bearing. The open design allows for easy maintenance and lubrication. KAA bearings are an ideal choice for applications like machine tool spindles, engines, transmissions, and industrial fans and blowers.

Exploring the KAA series open type deep groove ball thin section bearings:

The KAA Series represents a class of open type deep groove ball thin section bearings engineered for exceptional performance and efficiency. These bearings are designed to excel in a variety of applications where precision and load capacity are paramount.

KAA series open type deep groove ball thin section bearings features and benefits:

- Enhanced Load Handling: The KAA series of open deep groove ball thin section bearings can accurately withstand radial and axial loads, making them suitable for demanding operating conditions.

Precision Manufacturing: Precision manufacturing ensures minimal noise, less vibration and smoother motion control.

Extended Life: Specialized designs and materials can help extend bearing life, minimizing downtime and maintenance costs.

Open design allows for easy maintenance and lubrication

Made of high quality steel for durability

Cage centering design distributes balls evenly around the bearing

Sealed or shielded versions provide protection from contaminants

Meets or exceeds ISO dimensions and tolerances

Applications of KAA series open type deep groove ball thin section Bearings:

The KAA Series open type deep groove ball thin section bearings are versatile and find applications in various industries and equipment, including:

Aerospace

Robotics

Semiconductor

Industrial machinery

Machine tools

Medical devices and machines

Textile and printing machinery

Factors for consideration when choosing KAA series open type deep groove ball thin section bearings:

- Load Ratings: Explain how understanding load ratings ensures optimal bearing selection for specific applications.

- Material Selection: Discuss the availability of different materials (e.g., stainless steel, chrome steel) and their suitability for different environments.

- Sealing Options: Detail the various sealing options available to protect the bearings from contaminants and ensure prolonged performance.

- Lubrication Needs: Emphasize the importance of proper lubrication to reduce friction and maintain bearing health.

KAA series open type deep groove ball thin section bearings maintenance tips:

- Lubricate bearings with grease or oil recommended by manufacturer

- Clean bearings periodically to remove contaminants

- Inspect for wear, pitting, discoloration indicating damage or failure

- Replace bearings if they show signs of excessive wear or damage

- Follow manufacturer instructions for proper installation and fits

KAA series open type deep groove ball thin section bearings product parameters:

Conclusion:

In conclusion, the KAA Series open type deep groove ball thin section bearings stand as a testament to precision engineering and performance excellence. Their distinct attributes make them an indispensable choice for industries requiring accuracy, reliability, and load-bearing capabilities.

For expert guidance in selecting the ideal KAA Series open type deep groove ball thin section bearings to match your specific requirements, reach out to our knowledgeable team. Experience firsthand how our precision solutions can elevate your machinery’s efficiency and durability. Contact us today!

LKPB With more than 10 years of production experience

Supporting OEM service; 50 days return service; 7*24 hours technical support; Accept non-standard customization; Product comes with 12 months warranty

Please let us know the model and quantity of the product you need and we will get back to you as soon as possible!

FAQ

What is LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB,Located in Luoyang, which is a bearing manufacturing base in China, we are an enterprise focusing on the research, development and manufacture of precision bearings, mainly producing precision crossed roller bearings and rotary table bearings and various non-standard bearings with precision class of P5, P4 , P2 and VSP.

Are your products reliable?

The company strictly follows the ISO9001 quality system requirements for product quality control, relying on the professional technology of the bearing production base, the product quality is stable and cost-effective, and is well received by customers at home and abroad. The company adheres to the concept of “openness, professionalism and responsibility”, and strives to become a professional bearing application service provider. Welcome customers to negotiate, looking forward to sincere cooperation with you, willing to achieve a win-win situation with you!

Do you have export experience?

Luoyang LIKE Precisoin Machinery Co., Ltd has accumulated rich production experience in the past 10 years, supporting OEM service. Our products are exported to Germany, Italy, Korea, Japan, the United States, Belgium, Turkey and so on.

Contact information for LKPB?

Tel: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

Email: info@lkpbearing.com

What types of bearings do you mainly produce?

Top quality: Rotary Table Bearing ( YRT, YRTS, YRTM, ZKLDF series) ; Crossed Roller Bearing ( RA/RAU, RB, RU, RE, SX, XU, XSU, XR/JXR, CRB/CRBC, CRBH, CRBF, CRBS, CRBT series); Thin Section Bearings ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU series); Harmonic Reducer Bearings ( CSF, SHF series); Angular Contact Ball Bearing ( 718, 719, 70, 72 series); Hollow Rotary Platform Bearings ( ZK series); and Flexible Bearings ( F series, 3E series).

Does it support OEM?

Yes, We have experience working in this area

What are the application areas of bearings?

The main application areas of our products are precision rotary tables, machining center rotary tables, industrial robot joints and rotating, robotic rotating parts, CNC machine tools, automation industry, direct drive motors, precision instruments, radar, medical equipment and other industries.

How long does the order cycle take?

Regular models are in stock, reasonable prices, ready for delivery, non-standard precision bearings according to the requirements of the drawings and the number of 1-3 weeks delivery time