Introduction to Slewing Ring Bearings

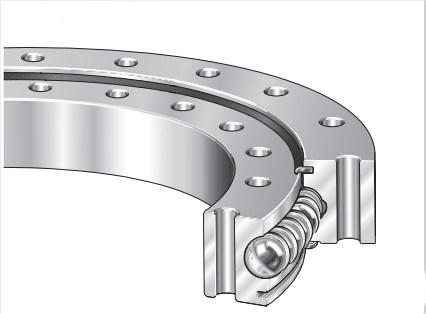

Slewing ring bearings, also known as slewing bearings or slewing rings, are specialized components designed to facilitate smooth and controlled rotational movements while supporting heavy radial and axial loads. These robust bearings are essential in a wide range of industrial machinery and equipment, enabling precise positioning and reliable operation under demanding conditions.

As the demand for high-performance and efficient machinery continues to grow, the incorporation of slewing ring bearings has become increasingly crucial across various industries. From construction and mining to renewable energy and industrial automation, these specialized bearings play a pivotal role in ensuring the smooth and reliable operation of critical equipment.

Benefit 1: Superior Load-Carrying Capacity

One of the primary advantages of using slewing ring bearings in your machinery is their exceptional load-carrying capacity. These bearings are engineered to withstand immense radial and axial loads, making them suitable for applications involving heavy loads and demanding operating conditions.

Slewing ring bearings are designed with robust internal components and specialized rolling elements, allowing them to support the combined weight of the machinery, payload, and dynamic forces encountered during operation. This high load-carrying capacity ensures the stability and durability of your machinery, reducing the risk of premature failure and minimizing downtime.

Benefit 2: Precise Rotational Movements

Slewing ring bearings are renowned for their ability to facilitate precise rotational movements, a critical requirement in many industrial applications. These bearings are manufactured with tight tolerances and advanced manufacturing processes, ensuring accurate positioning and minimal run-out.

The precise rotational movements enabled by slewing ring bearings are essential for applications such as radar systems, telescope mounts, and industrial robots, where even slight deviations in positioning can have significant consequences. By incorporating these bearings into your machinery, you can achieve exceptional accuracy and repeatability, resulting in improved product quality and operational efficiency.

Benefit 3: Customizable Solutions from LKPB

At LKPB, a leading slewing ring bearing manufacturer and supplier in China, we understand that every application has unique requirements. That’s why we offer customizable slewing ring bearing solutions tailored to meet your specific needs.

Our engineering team works closely with clients to design and manufacture slewing ring bearings that meet their exact specifications, ensuring optimal performance and reliability in even the most demanding applications. Whether you require specialized materials, coatings, or design modifications, we have the expertise and capabilities to deliver customized solutions that exceed your expectations.

In addition to custom solutions, LKPB also provides OEM (Original Equipment Manufacturer) services, partnering with manufacturers to integrate our slewing ring bearings seamlessly into their products, ensuring optimal performance and seamless integration.

Benefit 4: Durability and Longevity

Slewing ring bearings are designed to withstand harsh operating environments, making them ideal for use in machinery exposed to extreme conditions. These bearings are available in various material compositions and surface treatments, ensuring superior durability, corrosion resistance, and wear resistance.

At LKPB, we use premium raw materials and implement rigorous testing procedures to guarantee the longevity and performance of our slewing ring bearings. Our commitment to quality and adherence to international standards ensure that your machinery operates reliably for extended periods, reducing maintenance costs and maximizing uptime.

Benefit 5: Smooth and Efficient Operation

The smooth and efficient operation of your machinery is essential for achieving optimal productivity and minimizing energy consumption. Slewing ring bearings are renowned for their low-friction characteristics, enabling smooth and consistent performance while minimizing wear and tear on other components.

By incorporating slewing ring bearings into your machinery design, you can reduce vibrations and ensure smoother rotational movements, contributing to improved operational efficiency and reduced energy consumption. This not only enhances productivity but also promotes sustainability by minimizing the environmental impact of your operations.