About Bearings

Bearings are mechanical components that support rotating shafts or axles and enable smooth rotational motion between two parts. They are used in a wide range of applications, including motors, wheels, gears, and various kinds of machinery. Bearings serve several important functions:

1. Reducing friction: Bearings minimize the friction between the rotating shaft and the stationary housing, allowing for smoother rotation and reduced energy loss.

2. Supporting loads: Bearings are designed to support radial loads (perpendicular to the shaft) and, in some cases, thrust loads (parallel to the shaft).

3. Positioning: Bearings help maintain the proper positioning and alignment of the rotating components.

4. Distributing loads: Bearings distribute the load evenly across their rolling elements (e.g., balls, rollers), preventing localized stress and wear.

There are several types of bearings, including:

1. Ball bearings: These use small spherical balls as the rolling elements and are suitable for high-speed applications.

2. Roller bearings: These use cylindrical rollers as the rolling elements and can handle heavier radial loads.

3. Thrust bearings: These bearings are designed to support thrust loads parallel to the shaft.

4. Sleeve bearings: These are simple bushings or plain bearings that rely on a lubricating film between the shaft and the bearing surface.

Bearings can be made from various materials, such as steel, ceramic, or plastic, depending on the application’s requirements for load capacity, durability, and operating conditions (e.g., temperature, lubrication).

Proper selection, installation, and maintenance of bearings are crucial for ensuring efficient and reliable operation of rotating machinery.

China has made significant strides in developing its precision bearing industry in recent years. Here are some key insights:

- Increased focus on R&D: Chinese bearing manufacturers have been investing heavily in research and development to improve the quality, precision, and performance of their bearings. This has allowed them to catch up with international standards and compete more effectively in the global market.

- Adoption of advanced manufacturing technologies: Chinese companies have been adopting advanced manufacturing technologies, such as computer numerical control (CNC) machining, precision grinding, and surface treatment processes, to enhance the accuracy and reliability of their precision bearings.

- Expansion of product range: While China initially focused on producing standard bearings, many Chinese companies have expanded their product range to include high-precision bearings for various applications, including aerospace, automotive, and industrial machinery.

- Emphasis on quality control: To meet the stringent requirements of precision bearings, Chinese manufacturers have implemented robust quality control measures, such as clean-room environments, stringent inspection processes, and adherence to international quality standards like ISO 9001.

- Domestic market growth and international expansion: The growing demand for precision bearings in China’s domestic market, driven by industries like automotive, wind energy, and high-speed rail, has fueled the growth of the precision bearing industry. Additionally, Chinese bearing manufacturers have been actively pursuing international markets, leveraging their competitive pricing and improving quality.

- Collaboration and acquisitions: Some Chinese bearing companies have formed strategic partnerships or acquired foreign companies to gain access to advanced technologies, expertise, and established distribution networks.

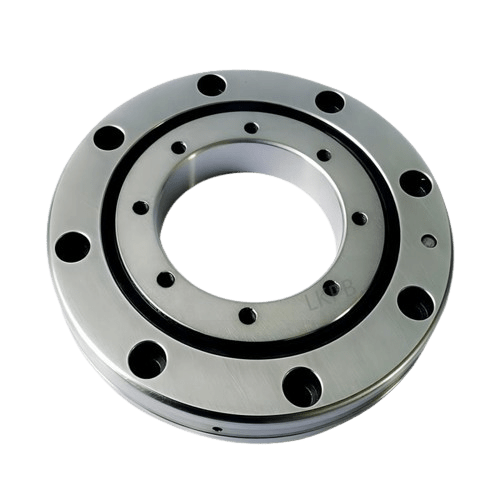

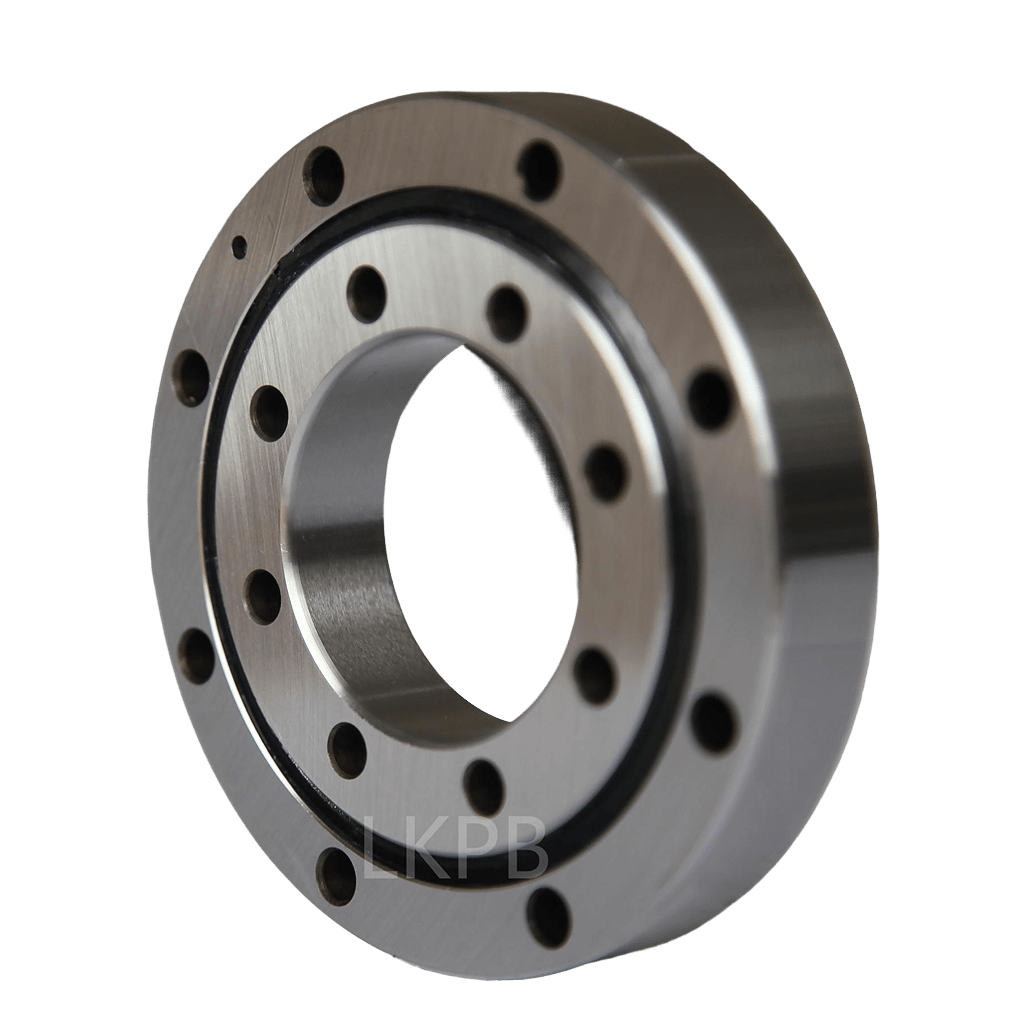

I nostri prodotti per cuscinetti di precisione

Our bearing applications

Informazioni sulla società di cuscinetti LKPB

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, Located in Luoyang, China, Established in 2013 with a registered capital of 5 million, We are a professional produttore di cuscinetti.

LKPB segue rigorosamente i requisiti del sistema di qualità ISO9001 per il controllo della qualità dei prodotti, disponiamo di un forte team tecnico per accettare l'elaborazione di cuscinetti di precisione non standard di livello di precisione P5, P4, P2 e VSP. La gamma di dimensioni del diametro interno dei prodotti è φ20mm-φ2000mm.

Abbiamo stabilito una cooperazione a lungo termine con alcune delle principali aziende di macchine utensili e robotica del mondo, i prodotti possono sostituire completamente INA/IKO/THK/FAG/SKF/KAYDON e altre marche. Crediamo che la collaborazione con noi supererà le vostre aspettative.

- Cuscinetti per tavole rotanti (Serie YRT, YRTC, YRTS, YRTM, ZKLDF) ;

- Cuscinetti a rulli incrociati (Serie RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF);

- Cuscinetti a sfere a sezione sottile (Serie KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU);

- Cuscinetti riduttori robot (CSF/CSG, SHF/SHG, serie CSD, cuscinetti riduttori RV e cuscinetti flessibili serie F, 3E);

- Cuscinetti a sfere a contatto obliquo (Serie 718, 719, 70, 72, 2344/2347);

- Cuscinetti di supporto per viti a ricircolo di sfere (Serie ZKLF/ZKLN, ZARF/ZARN);

- Anello di rotazione (a rulli incrociati, a quattro punti di contatto, a otto punti di contatto con lo stesso percorso, a otto punti di contatto con percorso diverso, a tre corone di rulli e flangiati);

- Cuscinetti a piattaforma rotante vuota ( Serie ZK).

Latest articles on bearings

Che cos'è un cuscinetto a mandrino laser?

A laser chuck bearing is a specialized type of bearing designed for high precision and high performance in laser cutting

Design innovativi per gli alloggiamenti dei cuscinetti nel 2024

Con la continua evoluzione del panorama industriale, gli alloggiamenti dei cuscinetti sono diventati componenti critici che richiedono design innovativi per soddisfare le diverse esigenze.

Le principali tendenze dei cuscinetti a flangia da osservare nel 2024

I cuscinetti a flangia sono componenti essenziali in un'ampia gamma di applicazioni industriali, in quanto forniscono un supporto affidabile e un movimento rotatorio uniforme per

Tipi innovativi di cuscinetti a rulli per applicazioni industriali nel 2024

In prossimità del 2024, il settore industriale sta assistendo a un'impennata della domanda di cuscinetti a rulli innovativi e ad alte prestazioni. Questi

Piccoli cuscinetti a rulli: Guida completa all'acquisto per il 2024

Nel mondo in continua evoluzione della meccanica di precisione, i piccoli cuscinetti a rulli svolgono un ruolo cruciale nel consentire un movimento fluido ed efficiente.

La guida definitiva alla scelta dei cuscinetti a rulli conici

I cuscinetti a rulli conici sono un tipo specifico di cuscinetto a rulli progettato per ospitare cuscinetti combinati radiali e radiali.

Per una guida esperta nel soddisfare le vostre esigenze specifiche, contattate il nostro team esperto. Scopri in prima persona come le nostre soluzioni di precisione possono aumentare l'efficienza e la durata dei tuoi macchinari. Contattaci oggi!

LKPB Con più di 10 anni di esperienza nella produzione

Supporto del servizio OEM; Servizio di reso entro 50 giorni; Supporto tecnico 7*24 ore; Accettare la personalizzazione non standard; Garanzia sul prodotto massima di 24 mesi