Introduction

The world of engineering has witnessed remarkable advancements in various domains, contributing to the overall progress of technology. Among these advancements, the development of rotary table bearing arrangements stands as a significant innovation, revolutionizing industries that rely on precision, efficiency, and controlled motion. A rotary table bearing arrangement serves as the backbone of numerous applications, ranging from manufacturing to aerospace and beyond. This essay delves into the intricate details, applications, design considerations, and advantages of rotary table bearing arrangements, shedding light on their pivotal role in modern engineering.

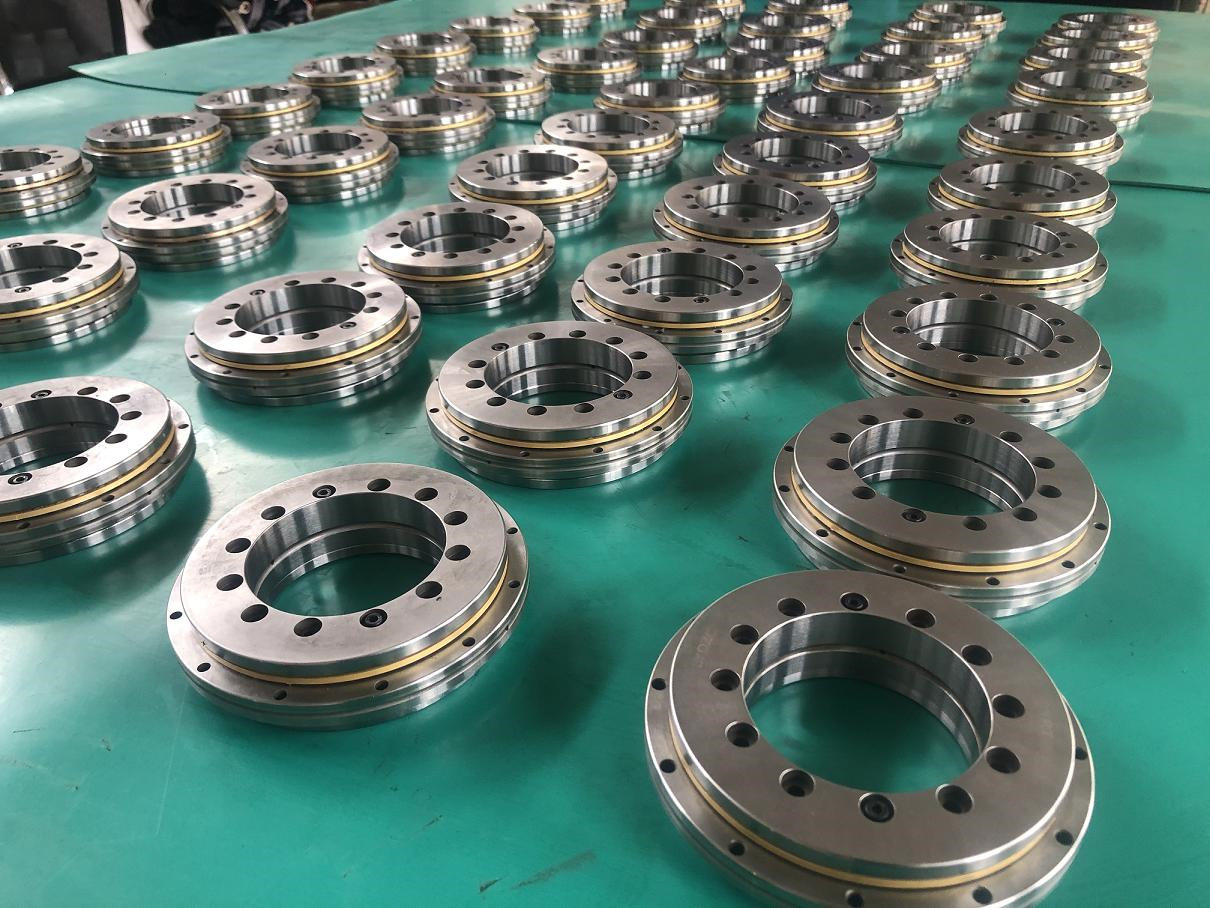

Understanding Rotary Table Bearing Arrangements

A rotary table bearing arrangement, in its essence, is a specialized mechanism designed to facilitate the rotational movement of heavy loads while minimizing friction and ensuring accurate positioning. It comprises a set of bearings, gears, and other mechanical components that work harmoniously to enable the controlled rotation of a platform or disc. This technology finds its application in a wide array of industries, including but not limited to machine tools, robotics, medical devices, and even entertainment systems.

Types of Rotary Table Bearing Arrangements

There are several types of rotary table bearing arrangements, each tailored to specific requirements and applications. The three main categories are:

-

Ball Bearings: Ball bearings utilize a series of balls to reduce friction and enable smooth rotation. They are suitable for moderate load applications where low friction and high precision are essential.

-

Roller Bearings: Roller bearings employ cylindrical or tapered rollers to distribute loads over a larger surface area. This type is better suited for heavier loads and can withstand axial and radial forces more effectively than ball bearings.

-

Slewing Bearings: Slewing bearings are designed to manage heavy axial and radial loads while simultaneously accommodating rotational movement. They often incorporate gear teeth around their periphery, allowing for the direct attachment of driving mechanisms.

-

Rotary Table Bearings: Rotary motion is a fundamental mechanical concept, and achieving it with utmost precision is vital for various applications such as machining, robotics, and astronomy. Rotary Table Bearings, often referred to as slewing bearings, are specialized components designed to support axial, radial, and moment loads while enabling smooth rotation. Their intricate design involves a ring-like structure with raceways, balls or rollers, and mounting provisions. The key advantage lies in their ability to support large loads while maintaining minimal rotational resistance.

Applications of Rotary Table Bearing Arrangements

The versatility of rotary table bearing arrangements is exemplified by their presence in various critical industries:

-

Manufacturing: In the manufacturing sector, precision is paramount. Rotary table bearing arrangements are used in machining centers, milling machines, and lathes to ensure accurate positioning of workpieces during the manufacturing process.

-

Aerospace: The aerospace industry relies on rotary table bearing arrangements for applications like flight simulators, satellite dish movement, and radar systems. These bearings guarantee the accurate tracking of celestial objects and provide stability in airborne systems.

-

Medical Devices: High-precision medical equipment, such as CT scanners and robotic surgical systems, benefit from rotary table bearing arrangements. They enable the precise movement required for imaging and surgical procedures, contributing to improved healthcare outcomes.

-

Robotics: Industrial robots heavily depend on rotary table bearing arrangements for their articulated arms. These bearings ensure controlled movement and positioning, enabling robots to perform intricate tasks with precision.

-

Entertainment: In the entertainment industry, rotary table bearing arrangements are employed in applications like rotating stages, amusement park rides, and even camera equipment for smooth panning and tilting movements.

Rotary Table Bearing Arrangements Design Considerations

Designing an effective rotary table bearing arrangement involves a deep understanding of mechanical engineering principles and a consideration of various factors:

-

Load Capacity: Determining the maximum load the arrangement will need to support is crucial in selecting the appropriate bearing type and size.

-

Friction and Efficiency: Minimizing friction is essential to ensure smooth rotation and energy efficiency. The choice between ball and roller bearings depends on the application’s requirements.

-

Accuracy and Precision: Applications demanding high precision necessitate bearings with tight tolerances and minimal backlash. This ensures that the rotational movement accurately corresponds to the desired output.

-

Environmental Conditions: Operating environments vary widely. Bearings used outdoors, for example, must withstand temperature fluctuations, moisture, and other environmental factors.

-

Maintenance and Durability: The ease of maintenance and the expected lifespan of the arrangement are crucial economic considerations. Proper lubrication, sealing, and material selection play a role in determining the arrangement’s longevity.

Advantages of Rotary Table Bearing Arrangements

The integration of rotary table bearing arrangements into various industries offers a plethora of advantages:

-

Precision and Accuracy: Rotary table bearing arrangements are engineered to provide exceptional precision, allowing for accurate positioning and controlled movements within micrometer-level tolerances.

-

High Load Capacity: The ability to handle substantial axial and radial loads makes rotary table bearing arrangements suitable for applications involving heavy equipment or structures.

-

Compact Design: These arrangements offer a compact solution for achieving rotational movement without requiring excessive space, making them ideal for applications with limited room for movement.

-

Reduced Friction: The utilization of advanced bearing technologies ensures minimal friction, contributing to energy efficiency and prolonged component life.

-

Smooth Motion: The design of rotary table bearing arrangements enables smooth and controlled motion, which is crucial in applications such as robotic arms, cameras, and rotating stages.

-

Customizability: Engineers can tailor rotary table bearing arrangements to suit specific needs by selecting the appropriate bearing type, size, and gear arrangement.

Challenges and Future Developments

While rotary table bearing arrangements offer remarkable benefits, they are not without challenges:

-

Complexity: Designing and assembling rotary table bearing arrangements can be intricate due to the precise alignment required for optimal performance.

-

Maintenance: Some applications, especially those exposed to harsh environments, might require frequent maintenance to ensure the arrangement’s longevity.

-

Cost: High-precision bearings and complex gear systems can lead to significant upfront costs, particularly for customized arrangements.

-

Space Limitations: In some industries, such as aerospace, the available space for bearing arrangements might be limited, requiring innovative design solutions.

Despite these challenges, ongoing advancements in materials, lubrication techniques, and manufacturing processes are paving the way for enhanced rotary table bearing arrangements. The integration of smart technologies, such as sensors and data analytics, could enable predictive maintenance strategies, further optimizing their performance and lifespan.

Rotary Table Bearing Introduction

Rotary Table Bearing ( YRT, YRTS, YRTM, ZKLDF series)

These bearings find applications in a myriad of industries. In manufacturing, Rotary Table Bearings enable precision rotary movement in machining centers, facilitating complex operations like multi-axis milling and simultaneous machining. In astronomy, they are employed in telescope mounts, allowing astronomers to track celestial objects with high accuracy. Robotics, too, benefits from these bearings, aiding in the articulation of robot arms and mechanisms with unmatched precision.

Conclusion

In the grand tapestry of engineering marvels, rotary table bearing arrangements stand as a testament to human ingenuity. These arrangements, with their precision, efficiency, and versatility, have revolutionized industries that rely on controlled motion and accurate positioning. From manufacturing to aerospace, medical devices to entertainment systems, the impact of rotary table bearing arrangements reverberates across countless applications.

As technology continues to evolve, it is likely that we will witness even more sophisticated iterations of these arrangements, addressing current challenges and pushing the boundaries of what is possible. As we move forward, let us not only appreciate the elegance of rotary table bearing arrangements but also anticipate the remarkable contributions they will make to shaping our future.