In the realm of industrial machinery and automation, precision and reliability are paramount. When it comes to rotary tables, one critical component that ensures smooth and accurate motion is the high precision rotary table bearing. In this article, we will explore the significance of high precision rotary table bearings, their key features, applications, and how they contribute to achieving optimal performance in various industrial sectors.

Understanding High Precision Rotary Table Bearings

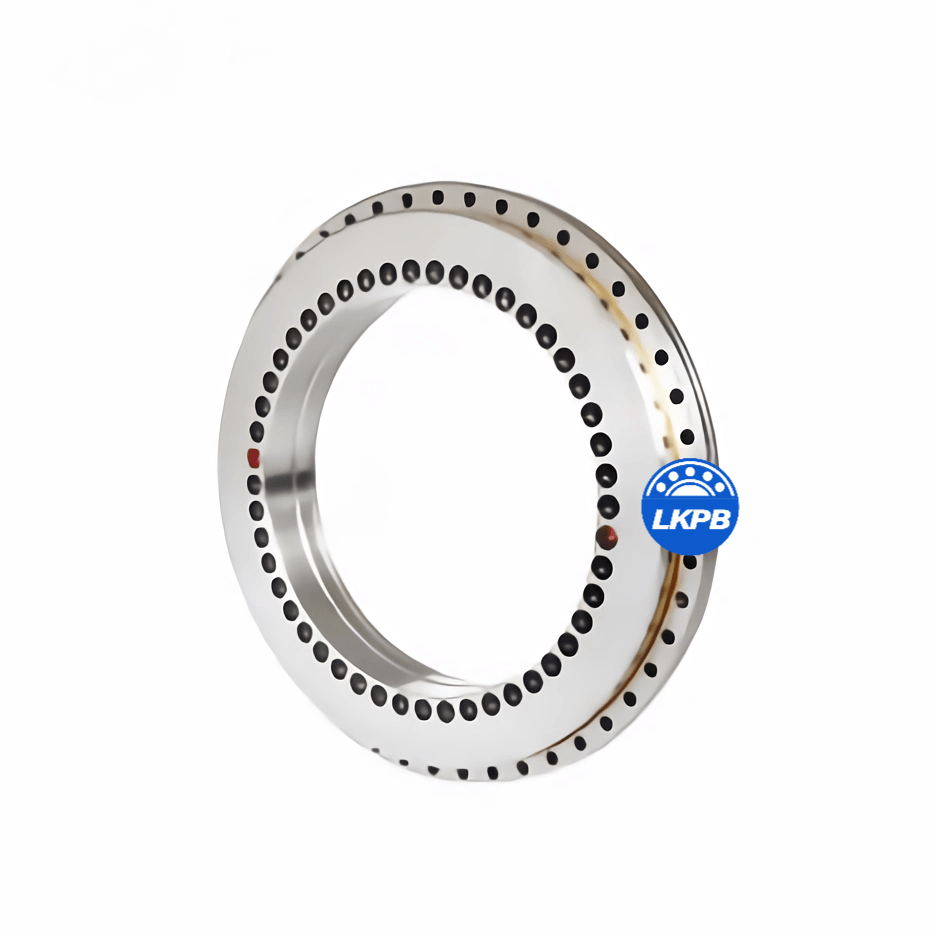

High precision rotary table bearings are specially designed to support rotational motion in machines such as indexing tables, turntables, and other rotary positioning systems. These bearings are engineered with meticulous attention to detail, incorporating advanced technologies and materials to deliver exceptional precision, stiffness, and load-carrying capacity.

Key Features and Design Principles

a. Precision: High precision rotary table bearings are manufactured with tight tolerances, allowing for minimal runout and axial clearance. This precision ensures accurate and repeatable positioning, crucial for applications demanding high levels of accuracy.

b. Rigidity: The design of these bearings focuses on maximizing stiffness to minimize deflection during operation. This rigidity improves overall system stability, enabling higher cutting forces, increased productivity, and improved surface finish in machining applications.

c. Load Capacity: High precision bearings are engineered to handle heavy loads while maintaining performance. They utilize specialized ball or roller elements and optimized raceway designs to provide exceptional load-carrying capabilities, ensuring reliable operation even under demanding conditions.

d. Sealing and Lubrication: To safeguard against contamination and enhance longevity, high precision rotary table bearings often incorporate advanced sealing mechanisms to prevent the ingress of contaminants. Additionally, they employ efficient lubrication systems, ensuring smooth motion and reducing friction.

Applications of High Precision Rotary Table Bearings

a. Machine Tools: Rotary tables are extensively used in machine tool applications, including milling, drilling, grinding, and EDM (electrical discharge machining). High precision bearings enable precise angular positioning, facilitating intricate operations and improving productivity.

b. Robotics and Automation: Rotary tables find applications in robotic systems and automated assembly lines. The high precision and rigidity of these bearings enable precise positioning and rotational movements, ensuring accurate and efficient automated processes.

c. Metrology and Inspection Systems: High precision rotary table bearings are crucial in metrology and inspection equipment, where accuracy and repeatability are essential. These bearings facilitate precise angular measurements, enabling quality control and dimensional accuracy in various industries.

d. Semiconductor Manufacturing: The semiconductor industry relies on high precision rotary tables for wafer handling, alignment, and lithography processes. The exceptional accuracy and stability of these bearings contribute to achieving nanoscale precision in semiconductor manufacturing.

Benefits of High Precision Rotary Table Bearings

a. Enhanced Accuracy: The exceptional precision of these bearings ensures accurate positioning, minimizing errors and improving the overall quality of manufactured components.

b. Improved Efficiency: High precision rotary table bearings enable faster cycle times, higher cutting speeds, and improved productivity in machining and automation processes.

c. Longer Service Life: With superior design, materials, and sealing mechanisms, these bearings offer extended service life, reducing downtime and maintenance costs.

d. Versatility: High precision rotary table bearings are available in various configurations, allowing customization to suit specific application requirements.