Angular contact bearings are a crucial component in many mechanical applications, offering high load capacity and precise control. As we move into 2024, the technology and applications for these bearings continue to evolve. This guide aims to provide a comprehensive overview of angular contact bearings, focusing on their features, benefits, and applications, as well as insights into custom and OEM solutions available from leading suppliers like LKPB. Whether you are an engineer, a procurement manager, or simply interested in understanding more about these essential components, this guide will provide valuable information.

What are Angular Contact Bearings?

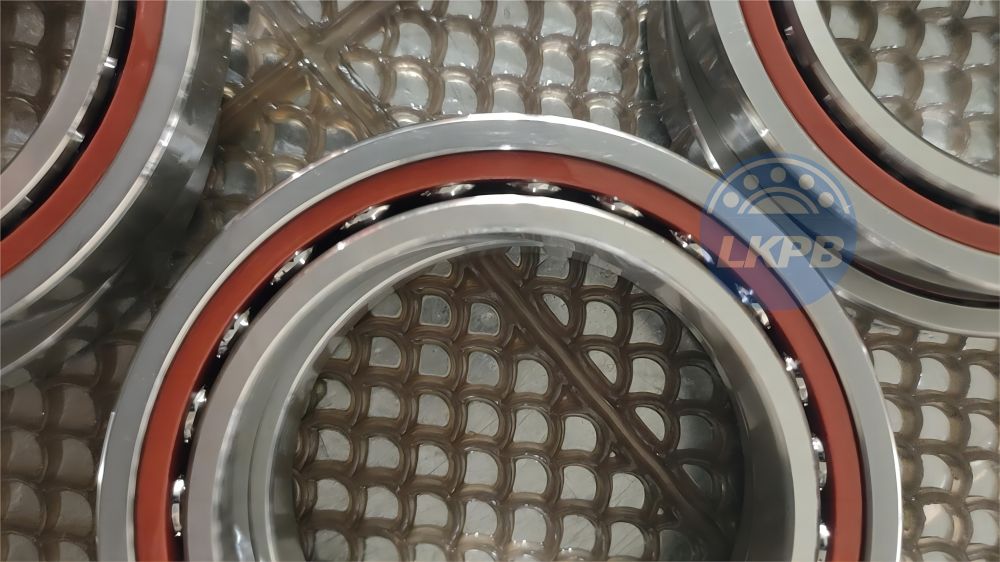

Angular contact bearings are designed to handle both radial and axial loads, making them highly versatile. They are used in applications where high precision and rigidity are required. The unique design allows the bearing to support loads that act at an angle relative to the bearing’s axis. This is achieved through the angular displacement between the inner and outer rings.

Key Features and Benefits

Angular contact bearings are distinguished by their ability to manage combined loads. Here are some of their key features and benefits:

- Load Capacity: These bearings can handle higher axial loads compared to radial bearings, thanks to the angle of contact.

- Precision: High precision is achieved due to the specific contact angle, which helps in applications requiring tight tolerance.

- Speed: They are suitable for high-speed applications, making them ideal for use in machinery like turbines and pumps.

- Versatility: Available in various configurations, including single-row, double-row, and four-point contact bearings, to suit different application needs.

Common Applications

Angular contact bearings are used in numerous industries, including automotive, aerospace, manufacturing, and robotics. Some common applications include:

- Machine Tools: High precision and load capacity make them ideal for CNC machines and other tooling equipment.

- Automotive: Used in gearboxes and other high-stress components.

- Aerospace: Critical for components that require both precision and durability.

- Medical Equipment: Essential for devices that need high precision and reliability.

Selecting the Right Angular Contact Bearing

Choosing the right angular contact bearing involves several factors. Understanding these can help ensure optimal performance and longevity.

Load Requirements

Determine the types and magnitudes of loads the bearing will encounter. Angular contact bearings can handle both radial and axial loads, but the ratio between these loads will affect the bearing selection.

Precision Levels

The level of precision required for your application will influence your choice. Bearings come in various precision grades, and selecting the appropriate one is crucial for applications requiring high accuracy.

Speed and Temperature

Consider the operational speed and temperature. Bearings designed for high-speed applications may feature specific materials and lubrication to withstand the stresses involved.

Bearing Supplier and Manufacturer

Working with a reputable bearing supplier and manufacturer like LKPB ensures access to high-quality bearings. LKPB offers a range of standard and custom solutions, ensuring that you can find the exact bearing to meet your specific needs.

Understanding Bearing Configurations

Angular contact bearings come in various configurations, each designed to meet specific requirements. Understanding these configurations can help in selecting the right bearing for your application.

Single-Row Angular Contact Bearings

Single-row angular contact bearings are designed to accommodate axial loads in one direction. They are commonly used in applications where combined loads are prevalent. These bearings are ideal for use in precision instruments and high-speed applications.

Double-Row Angular Contact Bearings

Double-row bearings can handle axial loads in both directions and are suitable for applications requiring a high load capacity. They are often used in pumps, compressors, and other machinery where stability and load distribution are critical.

Four-Point Contact Bearings

Four-point contact bearings can support axial loads in both directions and have a high load-carrying capacity. They are typically used in applications with high axial loads, such as in the main spindles of machine tools.

Custom and OEM Solutions with LKPB

One of the significant advantages of working with a leading bearing manufacturer like LKPB is the availability of custom and OEM solutions. This flexibility ensures that you get bearings tailored to your specific requirements, enhancing performance and efficiency.

Non-Standard Customization

LKPB excels in providing non-standard customization options. Whether you need a bearing with specific dimensions, materials, or performance characteristics, LKPB can develop a solution that meets your exact needs. This customization capability is particularly valuable in industries where unique requirements are the norm.

OEM Partnerships

For original equipment manufacturers (OEMs), partnering with LKPB offers several benefits. LKPB’s expertise in bearing design and manufacturing ensures that you receive high-quality components that integrate seamlessly into your products. This partnership can lead to improved product performance and reliability, giving you a competitive edge in the market.

Maintenance and Care for Angular Contact Bearings

Proper maintenance and care are essential to ensure the longevity and optimal performance of angular contact bearings. Regular maintenance can prevent premature failure and extend the bearing’s operational life.

Lubrication

Lubrication is crucial for the smooth operation of bearings. Ensure that the correct type and amount of lubricant are used. Regularly check and replenish the lubricant to maintain optimal performance.

Alignment and Installation

Proper alignment and installation are critical. Misalignment can lead to uneven load distribution, increasing wear and reducing the bearing’s lifespan. Ensure that bearings are installed using the correct tools and procedures.

Regular Inspections

Conduct regular inspections to identify signs of wear or damage. Early detection of issues can prevent costly repairs and downtime. Look for symptoms such as unusual noise, vibration, or increased operating temperature.

Working with Your Bearing Supplier

Maintaining a good relationship with your bearing supplier, such as LKPB, can provide additional support. Suppliers can offer maintenance tips, replacement parts, and technical assistance, ensuring that your bearings remain in top condition.

Innovations and Trends in Angular Contact Bearings

As technology advances, so do the capabilities of angular contact bearings. Keeping abreast of the latest innovations and trends can help you make informed decisions and leverage new developments for your applications.

Advanced Materials

The use of advanced materials such as ceramics and high-performance alloys is becoming more prevalent. These materials offer improved performance, higher speed capabilities, and greater resistance to wear and corrosion.

Smart Bearings

The integration of sensors and smart technology into bearings is an emerging trend. Smart bearings can monitor their own condition, providing real-time data on temperature, vibration, and other critical parameters. This information can be used for predictive maintenance, reducing downtime and improving efficiency.

Sustainable Practices

There is a growing emphasis on sustainability in bearing manufacturing. This includes using eco-friendly materials, reducing waste in the manufacturing process, and developing bearings that require less energy to operate.

Customization and Flexibility

The demand for customized solutions continues to rise. Manufacturers like LKPB are investing in technologies and processes that allow for greater flexibility in design and production, ensuring that customers can get bearings that precisely meet their needs.