In the ever-evolving landscape of industrial machinery and equipment, precision slewing rings play a pivotal role in enabling smooth rotational movements. These specialized bearings are designed to handle heavy radial and axial loads while ensuring accurate positioning and reliable performance. As industries continue to push the boundaries of innovation, the demand for high-quality slewing ring suppliers has skyrocketed, particularly in manufacturing powerhouses like China. In this comprehensive guide, we’ll explore the world of precision slewing ring suppliers, focusing on the key factors to consider when sourcing these critical components from China.

Understanding the Importance of Precision Slewing Rings

Slewing Rings: The Unsung Heroes of Rotational Machinery: Slewing rings, also known as slewing bearings or rotating rings, are essential components found in a wide range of applications, including wind turbines, cranes, excavators, industrial robots, and radar systems. These specialized bearings facilitate smooth rotational movements while supporting heavy loads, ensuring precise positioning and minimizing wear and tear.

The Impact of Quality on Performance and Longevity: The performance and longevity of rotational machinery heavily rely on the quality of the slewing rings used. Inferior or poorly manufactured slewing rings can lead to excessive friction, premature wear, and even catastrophic failures, resulting in costly downtime, repairs, and potential safety hazards. By investing in high-quality precision slewing rings from reputable suppliers, you can mitigate these risks and maximize the operational efficiency and lifespan of your equipment.

Navigating the World of China Precision Slewing Ring Suppliers

Expertise and Industry Experience: When evaluating potential proveedores de coronas de orientación in China, their expertise and industry experience should be at the forefront of your assessment. Look for companies with a proven track record and a deep understanding of slewing ring applications, materials, and manufacturing processes. Suppliers with extensive industry knowledge can provide valuable insights and recommendations tailored to your specific requirements.

Manufacturing Capabilities and Quality Control: High-quality precision slewing rings are the result of stringent manufacturing processes and rigorous quality control measures. Investigate the supplier’s manufacturing facilities, technologies, and quality assurance protocols to ensure they adhere to industry standards and best practices. Reputable suppliers prioritize quality at every stage, from raw material sourcing to final product inspection.

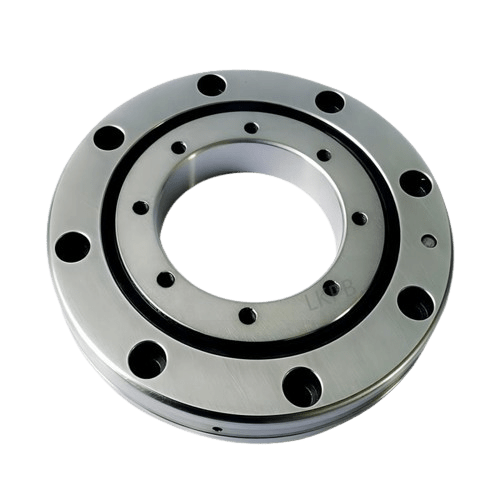

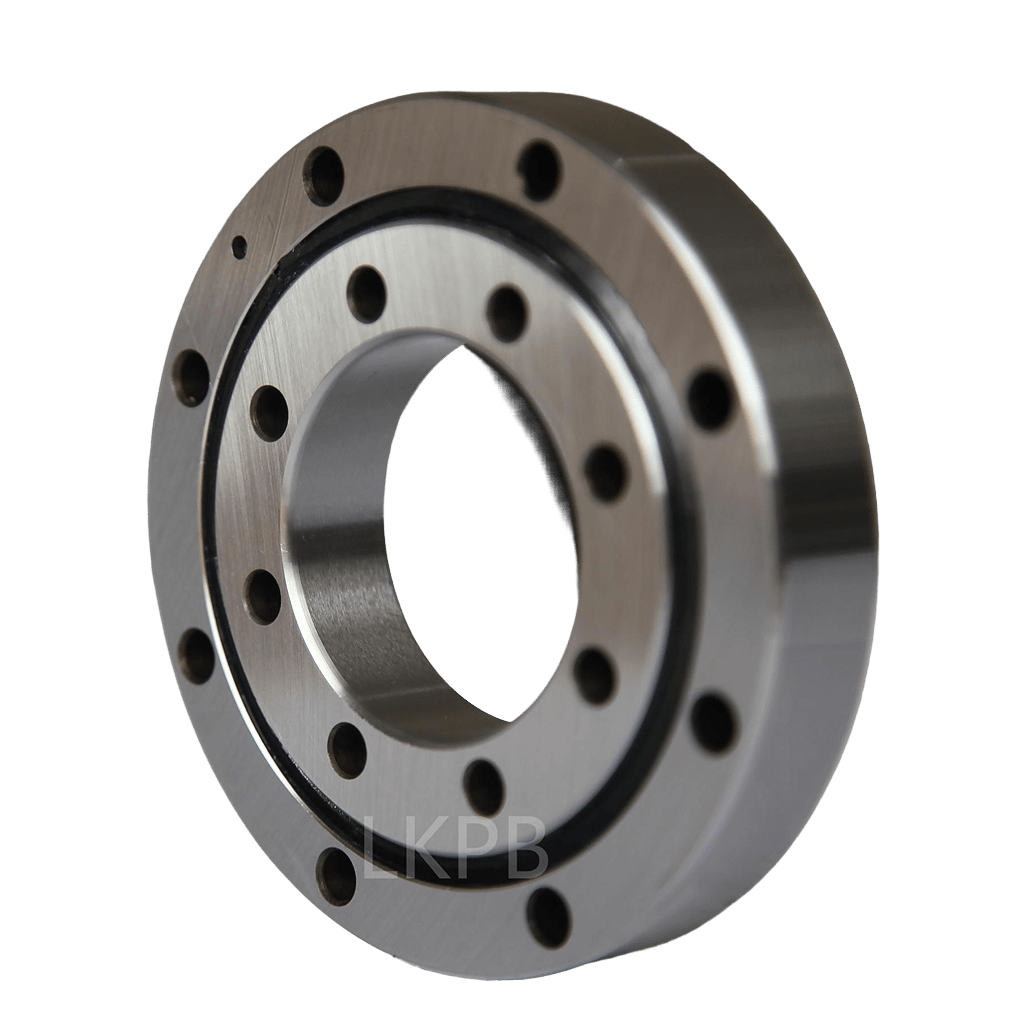

Customizable Solutions and OEM Services: In the dynamic world of industrial machinery, flexibility and adaptability are key. Look for slewing ring suppliers that offer customizable solutions and OEM (Original Equipment Manufacturer) services. Companies like LKPB excel in accommodating non-standard requirements, allowing you to optimize your machinery and equipment for specific applications or unique design constraints.

Global Sourcing and Supply Chain Efficiency: While China is a major hub for slewing ring production, consider suppliers with a global presence and sourcing capabilities. Suppliers with an international footprint can offer a wider range of options, access to diverse manufacturing facilities, and the ability to serve customers worldwide effectively. Additionally, evaluate their supply chain efficiency, including inventory management, shipping methods, and responsiveness to urgent orders.

Competitive Pricing and Value-Added Services: While cost should not be the sole deciding factor, finding a balance between quality and affordability is essential. Research and compare slewing ring prices from various suppliers to ensure you’re getting a fair deal without compromising on product quality or performance. Furthermore, look for suppliers that offer value-added services such as technical support, product training, and maintenance advice, which can help you maximize the lifespan and performance of your slewing rings.

The LKPB Advantage: A Trusted Partner for Precision Slewing Ring Solutions

LKPB has established itself as a leading supplier of precision slewing rings, renowned for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art manufacturing facilities and a team of experienced engineers, LKPB offers a comprehensive range of slewing rings tailored to meet the demands of diverse industries.

Embracing Customization and OEM Services: Understanding the unique challenges faced by its customers, LKPB excels in providing customizable slewing ring solutions and OEM services. Whether you require slewing rings for specialized machinery, extreme operating conditions, or unique design constraints, LKPB’s expertise in custom slewing ring design ensures that you obtain products that meet your exact specifications, reducing the need for costly modifications or compromises.

Quality Assurance and Rigorous Testing: At LKPB, quality is ingrained in every aspect of their operations. From stringent raw material inspections to comprehensive product testing, LKPB adheres to the highest industry standards and quality control measures. This unwavering commitment to quality ensures that every slewing ring leaving their facilities meets or exceeds performance expectations, providing you with peace of mind and reliable operation.

Competitive Pricing and Value-Added Support: LKPB understands the importance of balancing quality with affordability. By leveraging their global sourcing capabilities and streamlined supply chain, they offer competitive pricing without sacrificing quality. Additionally, LKPB provides value-added services such as technical support, product training, and maintenance advice, ensuring that you can maximize the lifespan and performance of their slewing rings.

By choosing LKPB as your trusted precision slewing ring supplier, you gain access to a partner that prioritizes quality, innovation, and customer satisfaction. With their expertise in customization, commitment to rigorous testing, and value-added support, LKPB positions itself as a reliable choice for businesses seeking exceptional rotary solutions.

Unlock the Power of Precision and Reliability

In the dynamic world of industrial machinery and equipment, precision slewing rings play a crucial role in enabling smooth rotational movements and reliable performance. By partnering with reputable precision slewing ring suppliers in China, you can gain access to high-quality components that meet your unique requirements and drive operational excellence.

Remember, choosing the right slewing ring supplier is an investment in the longevity and efficiency of your machinery, ultimately impacting your bottom line and competitive edge. Embrace the pursuit of quality, seek out suppliers that offer customizable solutions and value-added services, and prioritize partnerships that foster innovation and continuous improvement.

With a strategic approach and the right precision slewing ring supplier by your side, you can unlock a world of precision and reliability, where seamless rotational movements, reduced downtime, and optimized productivity become the norm. Embark on this journey today and experience the transformative power of superior rotary solutions from China’s leading precision slewing ring suppliers.

Productos de coronas giratorias LKPB

Para obtener orientación experta para cumplir con sus requisitos específicos, comuníquese con nuestro equipo experto. Experimente de primera mano cómo nuestras soluciones de precisión pueden elevar la eficiencia y durabilidad de su maquinaria. ¡Póngase en contacto con nosotros hoy!

LKPB Con más de 10 años de experiencia en producción.

Servicio OEM de soporte; Servicio de devolución de 50 días; Soporte técnico 7*24 horas; Aceptar personalización no estándar; Garantía máxima del producto de 24 meses

¡Háganos saber el modelo y la cantidad del producto que necesita y nos comunicaremos con usted lo antes posible!

Preguntas más frecuentes

¿Qué es LKPB?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, la precisión del producto puede ser P5, P4, P2 y VSP, rango de tamaño del diámetro interior φ20 mm – φ2000 mm. Garantía máxima de calidad del producto de 24 meses, OEM aceptable.

LKPB Con más de 10 años de experiencia en producción, los proveedores más profesionales de rodamientos de precisión en China.

¿Son sus productos confiables?

LKPB® Sigue estrictamente los requisitos del sistema de calidad ISO9001 para el control de calidad del producto, confiando en la tecnología profesional de la base de producción de rodamientos, la calidad del producto es estable y rentable.

LKPB®, girando el mundo, llevando ilimitado! Hemos atendido a miles de clientes en todo el mundo durante los diez años de nuestra creación.

Nuestro objetivo futuro es convertirnos en el fabricante más profesional de rodamientos para mesa giratoria y rodamientos de rodillos cruzados en China, y fabricar LKPB® una marca de rodamientos de clase mundial.

¡Ésta es nuestra visión y dirección!

¿Tiene experiencia en exportación?

LKPB® Ha acumulado una rica experiencia en producción en los últimos 10 años, respaldando el servicio OEM. Nuestros productos se exportan a Alemania, Italia, Corea, Japón, Estados Unidos, Bélgica, Turquía, etc.

¿Información de contacto de LKPB?

Teléfono: 0086-379 63123369

Whatsapp/Wechat: 86 15670310586

Correo electrónico: info@lkpbearing.com

¿Qué tipos de rodamientos produce principalmente?

1. Precisión Rodamientos de mesa giratoria ( YRT, YRTC, YRTS, YRTM, ZKLDF Series)

2. Precisión Rodamientos de rodillos cruzados ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/Serie CRBTF);

3. Precisión Rodamientos de sección delgada ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU);

4. Rodamientos reductores armónicos del robot (CSF/CSG, SHF/SHG, CSD Series, Rodamientos Reductores RV y Rodamientos flexibles F, Serie 3E);

5. Rodamientos de bolas de contacto angular ( 718, 719, 70, 72, 2344/2347 Serie);

6. Rodamientos de apoyo del husillo de bolas ( ZKLF/ZKLN, ZARF, ZARN Serie);

7. Rodamiento giratorio de precisión ( Rodillo cruzado, Contacto de cuatro puntos, Contacto de ocho puntos Mismo camino, Contacto de ocho puntos Camino diferente, Rodillo de tres hileras y con bridas);

8. Rodamientos de plataforma giratoria hueca (Serie ZK).

¿Es compatible con OEM?

Sí, tenemos experiencia trabajando en esta área.

¿Cuáles son las áreas de aplicación de los rodamientos?

Las principales áreas de aplicación de nuestros productos son mesas giratorias de precisión, mesas giratorias de centros de mecanizado, juntas y piezas giratorias de robots industriales, máquinas herramienta CNC, industria de automatización, motores de accionamiento directo, instrumentos de precisión, radares, equipos médicos y otras industrias.

¿Cuánto dura el ciclo del pedido?

Los modelos regulares están en stock, precios razonables, listos para la entrega, rodamientos de precisión no estándar de acuerdo con los requisitos de los dibujos y el tiempo de entrega de 1 a 3 semanas.