In the rapidly evolving field of robotics, collaboration between humans and machines has become a game-changer. Collaborative robots, also known as cobots, are designed to work alongside humans in various industrial and service applications, leveraging the strengths of both human intelligence and robotic precision. At the heart of these innovative robotic systems lies a crucial component – the flexible bearing – which plays a pivotal role in enabling safe, smooth, and efficient interactions between humans and cobots.

Understanding Collaborative Robots

Collaborative robots are a relatively new generation of robotic systems that are engineered to operate in close proximity to humans without the need for physical barriers or safety cages. These robots are designed with advanced sensors, control systems, and safety features that allow them to adapt to their surroundings and respond accordingly, ensuring the safety of both human workers and the robot itself.

Cobots are becoming increasingly popular in various industries, including manufacturing, healthcare, and logistics, where they assist human workers in tasks that require precision, repetition, or handling of heavy loads. By combining human dexterity and decision-making capabilities with robotic accuracy and strength, collaborative robots offer numerous benefits, such as increased productivity, improved ergonomics, and enhanced operational flexibility.

The Importance of Flexible Bearings in Collaborative Robotics

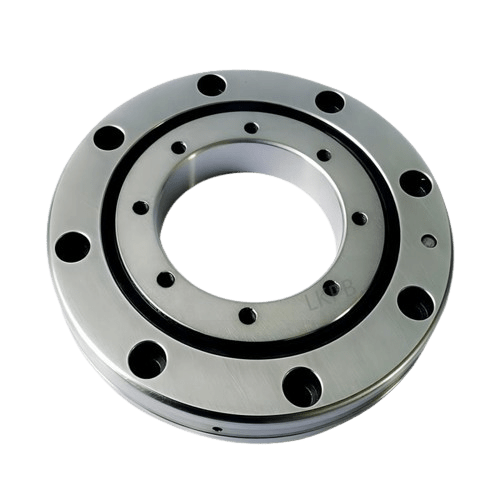

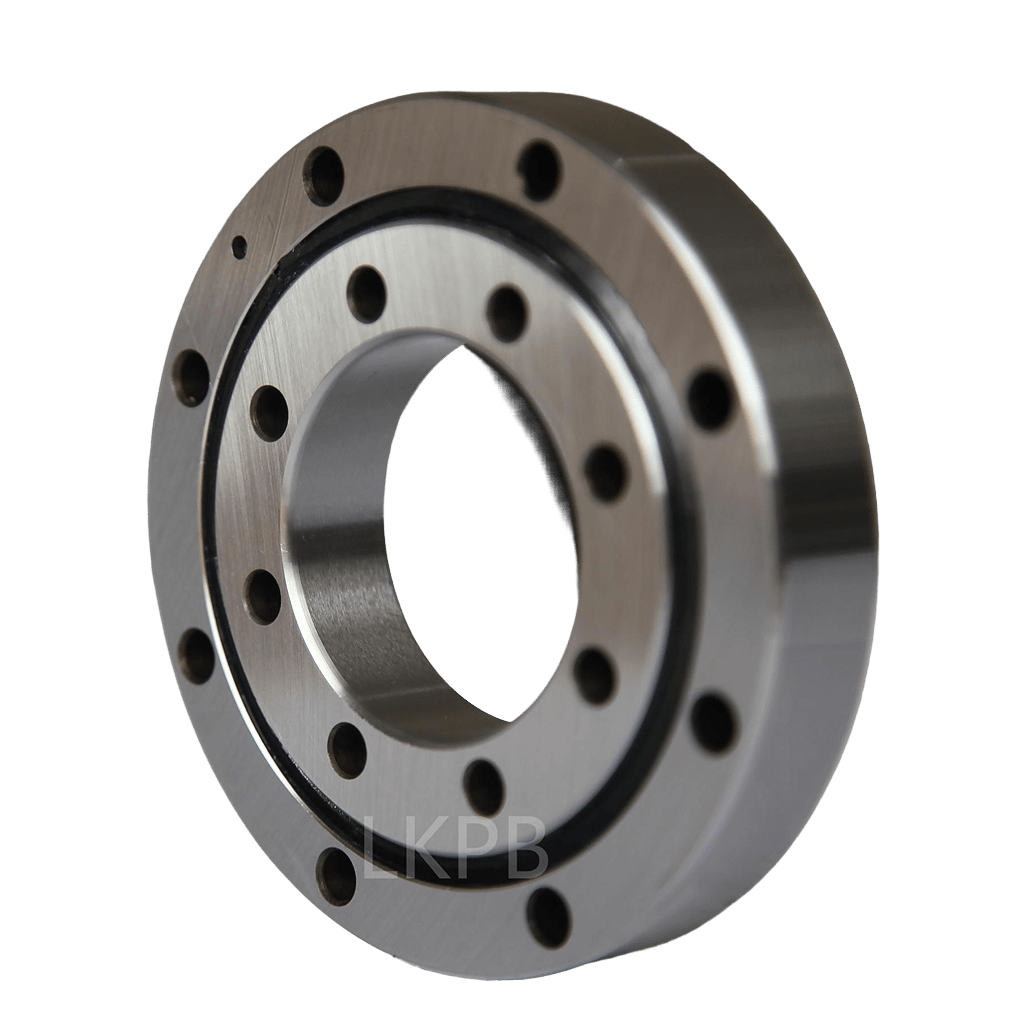

Flexible bearings, also known as harmonic drive bearings or wave bearings, are essential components in collaborative robotics applications. These specialized bearings are designed to provide smooth and controlled movements while accommodating misalignments and deflections, ensuring safe and reliable operation in close proximity to human workers.

The selection of the appropriate flexible bearing is crucial for the safe and efficient operation of collaborative robots. Key factors to consider include:

- Compact and Lightweight Design: Flexible bearings are designed with a compact and lightweight structure, making them suitable for integration into the lightweight and compact designs of collaborative robots.

- High Precision and Stiffness: Despite their flexibility, these bearings offer high precision and stiffness, enabling accurate positioning and controlled movements essential for collaborative robotic applications.

- Low Friction and High Efficiency: Flexible bearings exhibit low friction characteristics, resulting in high efficiency and reduced energy consumption, which is crucial for the energy-efficient operation of collaborative robots.

- Inherent Compliance: The ability of flexible bearings to accommodate misalignments and deflections contributes to the inherent compliance of collaborative robots, enhancing safety and reducing the risk of collisions with human workers.

- 사용자 지정 옵션: Manufacturers offer a wide range of customization options for flexible bearings, allowing for tailored solutions to meet specific performance, size, or material requirements of collaborative robotic systems.

In 2017, LKPB became a supplier of flexible bearings to French **company Collaborative Robots Project

Before 2016, this customer uses the flexible bearing is Taiwan’s TPI brand, after our sales staff’s continuous communication, in January 2017, the customer finally agreed to let us first provide LKPB qualification, introduction, quality management system and other information.

In February 2017, the customer decided to sample our F32 flexible bearings 100 sets, after receiving the customer’s sample list, our company attaches great importance to the business and technical seminars held in a hurry, the sample will be sent to France by international express mail, after the customer continuous uninterrupted 120 hours of testing, the sample passed once, 2018 began to have small batch of orders one after another, after and before the supplier Comparison, our harmonic flexible bearing’s life, warranty, precision and price are highly recognized by customers. From 2019, our company has become a stable and high quality supplier of France** company!

LKPB Robot Reducer Bearings

특정 요구 사항을 충족하는 데 대한 전문가의 안내를 받으려면 지식이 풍부한 당사 팀에 문의하세요. 당사의 정밀 솔루션이 어떻게 기계의 효율성과 내구성을 향상시킬 수 있는지 직접 경험해 보십시오. 오늘 저희에게 연락하십시오!

LKPB 10년 이상의 생산 경험 보유

OEM 서비스 지원; 50일 반품 서비스; 7*24시간 기술 지원; 비표준 사용자 정의를 허용합니다. 최대 24개월 제품 보증

필요한 제품의 모델과 수량을 알려주시면 최대한 빨리 연락드리겠습니다!

자주하는 질문

LKPB란 무엇인가요?

Luoyang LIKE Precision Machinery Co., Ltd – LKPB®, 제품 정밀도는 P5, P4, P2 및 VSP일 수 있으며 내경 크기 범위는 Φ20mm – Φ2000mm입니다. 최대 24개월의 제품 품질 보증, OEM 허용.

LKPB 10년 이상의 생산 경험을 바탕으로 중국에서 가장 전문적인 정밀 베어링 공급업체입니다.

귀하의 제품은 신뢰할 수 있습니까?

LKPB® 제품 품질 관리를 위한 ISO9001 품질 시스템 요구 사항을 엄격히 준수하며 베어링 생산 기지의 전문 기술을 바탕으로 제품 품질이 안정적이고 비용 효율적입니다.

LKPB®, 세상을 돌리고 무제한으로 운반하십시오! 우리는 설립된 10년 동안 전 세계 수천 명의 고객에게 서비스를 제공해 왔습니다.

우리의 미래 목표는 중국에서 가장 전문적인 회전 테이블 베어링 및 크로스 롤러 베어링 제조업체가 되는 것입니다. LKPB® 세계적인 베어링 브랜드입니다.

이것이 우리의 비전이자 방향입니다!

수출 경험이 있나요?

LKPB® 지난 10년간 풍부한 생산 경험을 축적해 OEM 서비스를 지원하고 있습니다. 당사의 제품은 독일, 이탈리아, 한국, 일본, 미국, 벨기에, 터키 등에 수출됩니다.

LKPB의 연락처 정보는 무엇입니까?

전화: 0086-379 63123369

WhatsApp/Wechat: 86 15670310586

이메일: info@lkpbearing.com

주로 어떤 종류의 베어링을 생산하시나요?

1. 정밀도 회전 테이블 베어링 ( YRT, YRTC, YRTS, YRTM, ZKLDF 시리즈)

2. 정밀도 크로스 롤러 베어링 ( RA/RA-C, RAU, RB, RU, RW, RE, SX, XU, XV, XSU, XR/JXR, CRB/CRBC, CRBF/CRBFV, CRBH/CRBHV, CRBS/CRBSV, CRBT/CRBTF 시리즈);

3. 정밀도 얇은 섹션 베어링 ( KAA, KA, KB, KC, KD, KF, KG, JHA, JA, JB, JG, JU 시리즈);

4. 로봇 고조파 감속기 베어링 (CSF/CSG, SHF/SHG, CSD 시리즈, RV 감속기 베어링 그리고 유연한 베어링 F, 3E 시리즈);

5. 앵귤러 콘택트 볼 베어링 ( 718, 719, 70, 72, 2344/2347 시리즈);

6. 볼 나사 지지 베어링 ( ZKLF/ZKLN, ZARF, ZARN 시리즈);

7. 정밀한 선회 베어링 ( 크로스 롤러, 4점 접촉, 8점 접촉 동일 경로, 8점 접촉 다른 경로, 3열 롤러 및 플랜지 시리즈);

8. 중공 로터리 플랫폼 베어링 (ZK 시리즈).

OEM을 지원합니까?

예, 우리는 이 분야에서 일한 경험이 있습니다

베어링의 적용 분야는 무엇입니까?

당사 제품의 주요 응용 분야는 정밀 회전 테이블, 머시닝 센터 회전 테이블, 산업용 로봇 조인트 및 회전, 로봇 회전 부품, CNC 공작 기계, 자동화 산업, 직접 구동 모터, 정밀 기기, 레이더, 의료 장비 및 기타 산업입니다.

주문주기는 얼마나 걸리나요?

일반 모델 재고 있음, 합리적인 가격, 배송 준비 완료, 도면 요구 사항 및 배송 시간 1~3주에 따른 비표준 정밀 베어링